Machining

|

3 Axis Surface Machining

|

Managing Geometry with User Machining Features

Customize the geometry tab page of a surface machining operation with

user machining features |

| Use Case |

Abstract

This article discusses the CAASmiUserOperationWithUserMF use case. It

explains how to customize the default geometry tab page of a surface

machining operation to be able to select geometry through an user

machining feature's geometry attribute.

This paper accompanies the first scenario of Surface Machining

Operation Sample [1].

|

What You Will Learn With This Use Case

This use case is intended to help you to manage geometry of a surface

machining operation with a machining feature geometry attribute.

More specifically, the CAASmiUserOperationWithUserMF Use Case shows how to:

- Overload the geometry tab page of a surface machining operation.

- Create a new machining feature.

- Connect a machining feature with a surface machining operation.

- Manage geometry selection of surface machining geometry attributes.

[Top]

The CAASmiUserOperationWithUserMF Use Case

CAASmiUserOperationWithUserMF is a use case of the CAASurfaceMachiningItf.edu

framework that illustrates Surface Machining capabilities. It is a part of the

sample described in the technical article [1].

[Top]

What Does CAASmiUserOperationWithUserMF Do

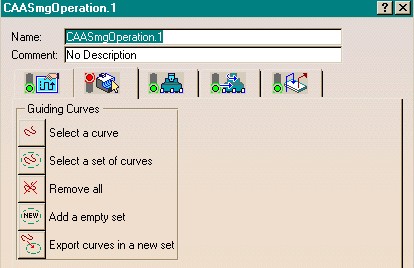

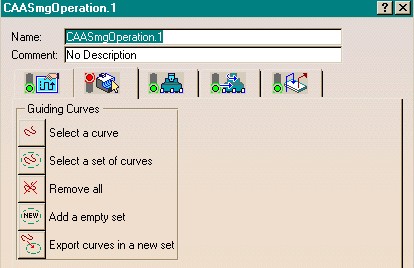

This use case customizes the default geometry tab page of CAASmgOperation.

CAASmgOperation is associated with a new machining feature: CAASmgMachiningFeature.

CAASmgMachiningFeature has a geometry attribute : CAASmgGuide. This

parameter can support manufacturing geometries or nc geometry features.

The geometry management is done by several functionalities:

|

Description of functionalities illustrated:

- Select a curve : select an edge with the edge selection

toolbar.

- Select a set of curves : select a NC Geometry Feature of

edges.

- Remove all : remove selection.

- Add a empty set : create an empty NC Geometry Feature of

edges.

- Export curves in a new set : create an NC Geometry Feature

with the edges previously selected.

|

[Top]

How to Launch CAASmiUserOperationWithUserMF

This use case is a part of Surface Machining Operation Sample [1].

You should build all the modules of this sample at a time to be able to launch

it [2].

Don't forget to edit the interface dictionary located in:

| Windows |

InstallRootDirectory\CAASurfaceMachiningItf.edu\CNext\code\dictionary\ |

| Unix |

InstallRootDirectory/CAASurfaceMachiningItf.edu/CNext/code/dictionary/ |

where InstallRootDirectory is the directory where the CAA CD-ROM

is installed, and uncomment the appropriate lines by removing the '#' character.

[Top]

Where to Find the CAASmiUserOperationWithUserMF Code

This use case is made of source files located in the

CAASmiUserOperationGeomUI.m module of the CAASurfaceMachiningItf.edu framework :

| Windows |

InstallRootDirectory\CAASurfaceMachiningItf.edu\CAASmiUserOperationGeomUI.m |

| Unix |

InstallRootDirectory/CAASurfaceMachiningItf.edu/CAASmiUserOperationGeomUI.m |

where InstallRootDirectory is the directory where the CAA CD-ROM

is installed.

[Top]

Step-by-Step

CAASmiUserOperationWithUserMF is divided into the following steps:

- Implementing CATIMfgGeometryActivity:

- Creating the geometry dialog frame:

We now comment each of those sections by looking at the code.

[Top]

Declaring CATIMfgGeometryActivity Implementation

To overload the geometry tab page, we should create an extension class that

will implement CATIMfgGeometryActivity:

...

// Tie the implementation to its interface

#include "TIE_CATIMfgGeometryActivity.h"

TIE_CATIMfgGeometryActivity( CAAESmiUserOperationGeometryEditor);

...

|

[Top]

Coding GetMainPanelEditor

In GetMainPanelEditor, we create a new CAASmgMachiningFeature

and we associate it with CAASmgOperation. Then we call the geometry

dialog frame described below.

...

// Associates a machining feature

CATIMfgActivity * pActivity = NULL;

oRC = QueryInterface(IID_CATIMfgActivity, (void**) &pActivity);

if (SUCCEEDED(oRC))

{

spMachFeature = pActivity->GetFeature();

if (NULL_var == spMachFeature)

{

// Create a user machining feature

oRC = CreateCAAMachiningFeature(spMachFeature);

if (SUCCEEDED(oRC))

{

// Link the machining feature to the activity

pActivity->SetFeature(spMachFeature);

}

}

pActivity->Release();

pActivity = NULL;

}

// Creates the frame

oFrame = new CAASmiUserOperationGeometryPanel(iFather,spMachFeature);

...

|

[Top]

Creating a New Machining Feature CAASmgMachiningFeature

The CreateCAAMachiningFeature method is used to create CAASmgMachiningFeature.

At first, we retrieve the startup of CAASmgMachiningFeature from the

catalog generated by CAASmiUserMachFeatureCatalog.m module.

...

// Loads catalog

CATUnicodeString CatalogFeature ("CAAUserMachiningFeatures.CATfct");

CATUnicodeString ClientID ("CAAManufacturing");

CATICatalog * pCatalogCont = NULL;

oRC = ::AccessCatalog (&CatalogFeature,&ClientID,spFeatCont,&pCatalogCont);

if (pCatalogCont == NULL) return oRC;

// Retrieves startup from catalog

CATBaseUnknown * pNewSUFeat = NULL;

CATUnicodeString NewSUFeatType("CAASmgMachiningFeature");

oRC = pCatalogCont->RetrieveSU(&pNewSUFeat,&NewSUFeatType,"CATISpecObject");

if (FAILED(oRC)) return oRC;

...

|

Then, we instanciate CAASmgMachiningFeature and we add the CAASmgGuide

attribute with the AddNcGeometryParameter method of CATISmgNcGeometryManager.

This method adds a geometry attribute which support standard geometries or nc

geometry features.

...

// Creates the machining feature (associated in Catalog)

if (pNewSUFeat)

{

CATISpecObject * pSpecSUFeat = NULL;

oRC = pNewSUFeat->QueryInterface(IID_CATISpecObject, (void**) &pSpecSUFeat);

if (SUCCEEDED(oRC))

{

oFeature = pSpecSUFeat->Instanciate("",spFeatCont);

// Adds a geometric parameter "CAASmgGuide"

if (!!oFeature)

{

CATISmgNcGeometryManager * pSmgManager = NULL;

oRC = oFeature->QueryInterface(IID_CATISmgNcGeometryManager, (void**) &pSmgManager);

if (SUCCEEDED(oRC))

{

oRC = pSmgManager->AddNcGeometryParameter("CAASmgGuide",SmgEdgeType);

pSmgManager->Release();

pSmgManager = NULL;

}

}

...

|

Finally, we add our feature in the Manufacturing Container.

...

// Adds the feature in the MfgView

SEQUENCE(CATBaseUnknown_ptr) ListOfMfgView = spFeatCont->ListMembers(CATIMfgViewAccess::ClassName());

int NbMfgView = ListOfMfgView.length();

if (NbMfgView)

{

CATBaseUnknown * pBaseView = ListOfMfgView[NbMfgView - 1];

if (pBaseView)

{

CATIMfgViewAccess * pMfgView = NULL;

oRC = pBaseView->QueryInterface(IID_CATIMfgViewAccess, (void**) &pMfgView);

if (SUCCEEDED(oRC))

{

pMfgView->AddFeature(oFeature);

pMfgView->Release();

pMfgView = NULL;

}

pBaseView->Release();

}

...

|

[Top]

Geometry Management: Coding SelectCurve

In CAASmiUserOperationGeometryPanel class, SelectCurve is

called whenever the user clicks on "Select a curve" button. It

calls the CAASmiUserOperationGeometrySelCom command that manages the

selection of standard geometries (edge or curve).

...

// Sends Selection command

new CAASmiUserOperationGeometrySelCom (this,_spGuide);

...

|

[Top]

Geometry Management: Coding SelectZone

In CAASmiUserOperationGeometryPanel class, SelectZone is called

whenever the user clicks on "Select a set of curves" button. It

activates the standard dialog editor of NC Geometry Features management via the CATIEdit

interface.

...

CATIEdit * pEdit = NULL;

HRESULT RC = _spGuide->QueryInterface(IID_CATIEdit, (void**) &pEdit);

if (SUCCEEDED(RC))

{

// For zone management

pEdit->Activate(NULL);

pEdit->Release();

pEdit = NULL;

}

...

|

[Top]

Geometry Management: Coding RemoveAll

In CAASmiUserOperationGeometryPanel class, RemoveAll is called

whenever the user clicks on "Remove all" button. It uses the RemoveAll

method of CATISmgNcGeometryParameter interface.

...

CATISmgNcGeometryParameter * pSmgParameter = NULL;

HRESULT RC = _spGuide->QueryInterface(IID_CATISmgNcGeometryParameter, (void**) &pSmgParameter);

if (SUCCEEDED(RC))

{

pSmgParameter->RemoveAll();

pSmgParameter->Release();

pSmgParameter = NULL;

}

...

|

[Top]

Geometry Management: Coding NewZone

In CAASmiUserOperationGeometryPanel class, NewZone is called

whenever the user clicks on "Add a empty set" button. A Nc

Geometry Feature is created by the CreateNcGeometryFeature method of CATISmgFactory.

The Nc Geometry Feature is added with Add method of CATISmgNcGeometryParameter.

...

// Creates a empty zone

CATISmgFactory * pSmgFactory = NULL;

HRESULT RC = spFeatCont->QueryInterface(IID_CATISmgFactory, (void**)&pSmgFactory);

if (SUCCEEDED(RC))

{

pSmgFactory->CreateNcGeometryFeature(SmgEdgeType,spNcFeature);

pSmgFactory->Release();

pSmgFactory = NULL;

}

// Adds it in the guide parameter

if (!!_spGuide && !!spNcFeature)

{

CATISmgNcGeometryParameter * pSmgParameter = NULL;

RC = _spGuide->QueryInterface(IID_CATISmgNcGeometryParameter, (void**) &pSmgParameter);

if (SUCCEEDED(RC))

{

pSmgParameter->Add(spNcFeature);

pSmgParameter->Release();

pSmgParameter = NULL;

}

}

...

|

[Top]

Geometry Management: Coding Export

In CAASmiUserOperationGeometryPanel class, Export is called

whenever the user clicks on "Export curves in a new set"

button. It uses the Export method of CATISmgNcGeometryParameter

interface.

...

CATISmgNcGeometryParameter * pSmgParameter = NULL;

HRESULT RC = _spGuide->QueryInterface(IID_CATISmgNcGeometryParameter, (void**) &pSmgParameter);

if (SUCCEEDED(RC))

{

pSmgParameter->Export();

pSmgParameter->Release();

pSmgParameter = NULL;

}

...

|

[Top]

In Short

This use case has demonstrated how to manage surface machining operation

geometry interactive with a geometry attribute of an user machining feature.

- It first shows how to implement the CATIMfgGeometryActivity

interface to overload default geometry tab page.

- Then, it shows how to create its own machining feature with a surface

machining geometry attribute.

- Finally, it describes geometry management illustrating the use of CATISmgNcGeometryParameter,

CATISmgNcGeometryManager and CATISmgFactory interfaces.

We will see now how to compute the tool path of our operation [3].

[Top]

References

History

| Version: 1 [Mar 2002] |

Document created |

| [Top] |

Copyright © 2002, Dassault Systèmes. All rights reserved.