Machining |

3 Axis Surface Machining |

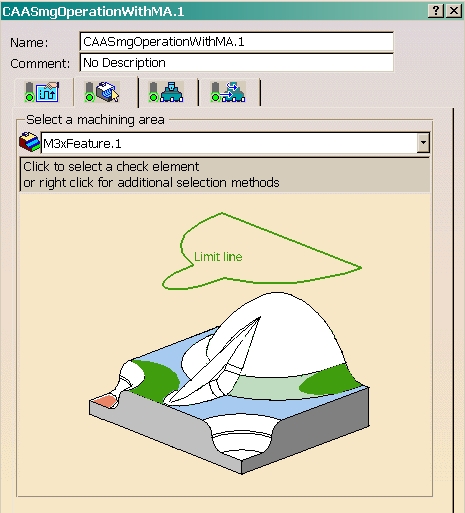

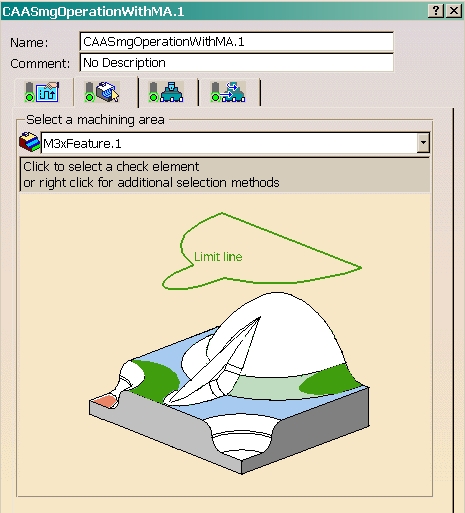

Managing Geometry with Machining AreasCustomize the geometry tab page of a surface machining operation with machining areas |

| Use Case | ||

AbstractThis article discusses the CAASmiUserOperationWithMA use case. It explains how to assign a surface machining operation to an existing machining area. This paper accompanies the second scenario of Surface Machining Operation Sample [1]. |

Machining areas are V5 SMG native features used to define different zones on a part.

This use case is intended to help you to manage geometry of a machining area assigned to a surface machining operation.

More specifically, the CAASmiUserOperationWithMA Use Case shows how to:

[Top]

CAASmiUserOperationWithMA is a use case of the CAASurfaceMachiningItf.edu framework that illustrates Surface Machining capabilities. It is a part of the sample described in the technical article [1].

[Top]

The goal of this use case is to define the geometry interactive of CAASmgOperationWithMA, using machining areas properties.

In the geometry tab page of CAASmgOperationWithMA, you can select a existing machining area and set its geometrical components (parts, checks, limit line and forbidden area):

[Top]

This use case is a part of Surface Machining Operation Sample [1]. You should build all the modules of this sample at a time to be able to launch it [2].

Don't forget to edit the interface dictionary located in:

| Windows | InstallRootDirectory\CAASurfaceMachiningItf.edu\CNext\code\dictionary\ |

| Unix | InstallRootDirectory/CAASurfaceMachiningItf.edu/CNext/code/dictionary/ |

where InstallRootDirectory is the directory where the CAA CD-ROM

is installed, and uncomment the appropriate lines by removing the '#' character.

[Top]

This use case is made of source files located in the CAASmiConnectUserOperationWithMA.m module of the CAASurfaceMachiningItf.edu framework:

| Windows | InstallRootDirectory\CAASurfaceMachiningItf.edu\CAASmiConnectUserOperationWithMA.m |

| Unix | InstallRootDirectory/CAASurfaceMachiningItf.edu/CAASmiConnectUserOperationWithMA.m |

where InstallRootDirectory is the directory where the CAA CD-ROM

is installed.

[Top]

CAASmiUserOperationWithMA is divided into the following steps:

We now comment each of those sections by looking at the code.

[Top]

To overload the geometry tab page, we should create an extension class that will implement CATIMfgGeometryActivity:

... // Tie the implementation to its interface #include "TIE_CATIMfgGeometryActivity.h" TIE_CATIMfgGeometryActivity( CAAESmiUserOperationWithMAGeometryEditor); ... |

In GetMainPanelEditor, we create a machining area (with CATISmgFactory) and associate it with CAASmgOperationWithMA. Then, we call the geometry dialog frame described below.

...

if (!!spFeatCont)

{

CATISmgFactory * pSmgFactory = NULL;

oRC = spFeatCont->QueryInterface(IID_CATISmgFactory, (void**) &pSmgFactory);

if (SUCCEEDED(oRC))

{

// Creates a empty machining area

oRC = pSmgFactory->CreateMachiningArea(spMachFeature);

if (SUCCEEDED(oRC))

{

// Link the machining area to the activity

pActivity->SetFeature(spMachFeature);

}

pSmgFactory->Release();

pSmgFactory = NULL;

}

...

}

// Creates the geometry frame

oFrame = new CAASmiUserOperationWithMAGeometryPanel(iFather,this);

...

|

[Top]

CAASmiUserOperationWithMAGeometryPanel is the frame of the geometry tab page of CAASmgOperationWithMA.

In the constructor class, we build a dialog combo filled with all the machining areas in the model and we add a event notification sent whenever a value is selected in the combo list. Then, we get the default dialog frame of the selected machining area with the CATIEdit interface.

...

// Creates a combo box

_pDlgCombo = new CATDlgCombo(this,"DlgCombo",CATDlgCmbDropDown);

if (_pDlgCombo)

{

...

// Fills the combo box

if (!!spFeatCont)

{

// Finds all machining areas inside the model

_pListOfMAs = spFeatCont->ListMembers("CATIM3xFeature");

int NumbOfMAs = _pListOfMAs.Size();

for (int i=1;i<=NumbOfMAs;i++)

{

CATUnicodeString Name;

CATBaseUnknown_var spMachArea = _pListOfMAs[i];

if (!!spMachArea)

{

CATIAlias * pAlias = NULL;

HRESULT RC = spMachArea->QueryInterface(IID_CATIAlias, (void**) &pAlias);

if (SUCCEEDED(RC))

{

Name = pAlias->GetAlias();

_pDlgCombo->SetLine(Name);

pAlias->Release();

pAlias = NULL;

}

if (spMachArea->IsEqual(spCurrentMachArea) == 1)

_pDlgCombo->SetSelect(i-1,0);

}

}

}

// Adds a callback

AddAnalyseNotificationCB(

_pDlgCombo,

_pDlgCombo->GetComboSelectNotification(),

(CATCommandMethod) &CAASmiUserOperationWithMAGeometryPanel::SelectMachArea,NULL);

// Creates the Machining Area editor

if (!!spCurrentMachArea)

{

CATIEdit * pEdit = NULL;

RC = spCurrentMachArea->QueryInterface(IID_CATIEdit, (void**) &pEdit);

if (SUCCEEDED(RC))

{

CATDlgFrame * pMAFrame = pEdit->GetPanelItem(this,"MAFrameID");

if (pMAFrame)

pMAFrame->SetGridConstraints( 1, 0, 2, 1, CATGRID_4SIDES);

pEdit->Release();

pEdit = NULL;

}

}

...

|

The SelectMachArea method is called whenever a new machining area is selected in the combo list. Here, the default dialog frame is updated with the CATIEdit interface:

...

// Refresh Machining Area Editor

CATIEdit * pEdit = NULL;

RC = spMA->QueryInterface(IID_CATIEdit, (void**) &pEdit);

if (SUCCEEDED(RC))

{

// As a frame called "MAFrameID" has already been created, the method GetPanelItem

// will refresh it

pEdit->GetPanelItem(this,"MAFrameID");

pEdit->Release();

pEdit = NULL;

}

...

|

[Top]

This use case has demonstrated how to use machining areas with a surface machining operation.

We will see now how to compute the tool path of our operation [3].

[Top]

| [1] | Surface Machining Operation Sample Overview |

| [2] | Building and Launching a CAA V5 Use Case |

| [3] | Computing a Tool Path with Machining Areas |

| [Top] | |

| Version: 1 [Mar 2002] | Document created |

| [Top] | |

Copyright © 2002, Dassault Systèmes. All rights reserved.