Mechanical Modeler

Retrieving Mechanical Import Information using GUID Mechanism

Using CATIMmiMechanicalImportApplicative with GUID as authentication

AbstractThe Use Case creates a Mechanical Import It begins by copying a feature between two Part documents using the "Copy as Result with Link" option. This results in a Mechanical Import [ 1]. It further illustrates the steps involved to authorize retrieving information from this Mechanical Import. This includes generating a GUID [2] and specifying it to the copy process, so that it gets associated with the Mechanical Import. This GUID, finally authorizes us to seek all relevant information from the copied feature. |

What You Will Learn With This Use Case

This use case is intended to show you how to retrieve the relevant

information from the Mechanical Import and how to create and use the

GUID for copying as well as for retrieving

relevant information. For these

purpose Use case uses two interfaces:

- CATMmrInterPartCopy

- CATIMmiMechanicalImportApplicative

CATMmrInterPartCopy: class services to copy a feature.

You will use this interface to copy a feature. You can read the referenced use case to learn more about this class [3].

CATIMmiMechanicalImportApplicative: The interface to retrieve the information from the copied feature. The information are

- The original feature

- The product instance ( if the copy is in assembly context)

SetImportApplicativeId and

SetApplicativeId methods uses GUID

associated with copied feature. SetImportApplicativeId sets

the GUID just prior to copying

operation and

SetApplicativeId sets the GUID after the copying operation for information retrieving.

[Top]

The CAAMmrApplicativeImport Use Case

CAAMmrApplicativeImport is a use case of the CAAMechanicalModeler.edu framework that illustrates MecModInterfaces framework capabilities.

[Top]

What Does CAAMmrApplicativeImport Do

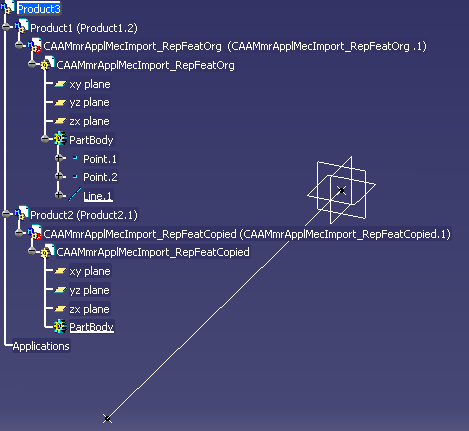

The Use Case fundamentally copies a feature from a source Part to a target Part, both in Assembly context and out of it, and further retrieves relevant information from the copied feature. It operates on an Input Model as the one depicted in Fig. 1 below.

|

Suppose you want to copy the Line.1 feature then

at the end of the Use Case execution, the Line.1

feature from CAAMmrApplMecImport_RepFeatOrg

is copied within the target Part

CAAMmrApplMecImport_RepFeatCopied, in assembly context as

well as out of assembly context. Mechanical Import is the result of feature copy, it is a feature returned

by the Run method. It is also valid for Point, Line, Curve and Plane.

But take care, suppose you try to copy BodyPart, Geometrical Set, Sketch feature, the feature returned by the Run

method is not a Mechanical Import itself but the features beneath it are the

Mechanical Import, this is properly explained in the technical article[1].

Most importantly, the Use Case illustrates the failure to

retrieve the relevant information (source feature and Product Instance) from

the copied feature, if you do not have the proper authorization for this

retrieval. It further illustrates to us a mechanism to authorize

retrieval of data by associating the copied feature with a GUID (using the CATIMmiMechanicalImportApplicative

Interface) during the copying process.

The creation of GUID is illustrated in step by

step section.

[Top]

How to Launch CAAMmrApplicativeImport

To launch CAAMmrApplicativeImport, you will need to set up the build time environment,

then compile CAAMmrApplicativeImport along with its prerequisites, set up the run time

environment, and then execute the use case [4].

To launch the use case execute the command:

mkrun -c "CAAMmrApplicativeImport

InputPath Feature"

where

$InstallRootDirectory\CAAMechanicalModeler.edu\InputData

Example:

mkrun -c "CAAMmrApplicativeImport

$InstallRootDirectory\CAAMechanicalModeler.edu\InputData Point.1"

[Top]

Where to Find the CAAMmrApplicativeImport Code

The CAAMmrApplicativeImport use case is located in the

CAAMmrApplicativeImport.m module of the

CAAMechanicalModeler.edu framework:

InstallRootDirectory\CAAMechanicalModeler.edu\CAAMmrApplicativeImport.m\ |

where InstallRootDirectory [4]

is the directory where the CAA CD-ROM

is installed.

[Top]

Step-by-Step

There are two logical parts in CAAMmrApplicativeImport, first part is

consist of generation of GUID and second part is a batch which consist

of operations like Copying feature with and without assembly context as

well as retrieving of information from the Mechanical Import.

Creating the GUID

- Generating the GUID

uuidgen is a command, generates the header file which contains

GUID. We

need to run this command on windows prompt and create the header file.

- Edit the header file

replace INTERFACENAME word by GUID CAAMmrGUIDForApplicativeImport, and remove the comments /*.... */

#ifndef CAAMmrGUIDForApplicativeImport_H #define CAAMmrGUIDForApplicativeImport_H GUID CAAMmrGUIDForApplicativeImport = {/* 7c7b3737-5358-0000-0280-020b3e000000 */0x7c7b3737, 0x5358, 0x0000, {0x02, 0x80, 0x02, 0x0b, 0x3e, 0x00, 0x00, 0x00} }; #endif

The CAAMmrUUIDForApplicativeImport.h

can be located in any *Interfaces directory, based on the scope within which

it is accessed by the client applications. Please note that the same

GUID can be associated with any number of Mechanical

Imports.

Second part is also divided in several logical steps:

- Make the Copy

- Set information relevant for feature copy

- Using GUID to be kept by the Mechanical Import

- Copy feature to target part

- Retrieve information from the copied feature using CATIMmiMechanicalImportApplicative

- Reset the CATMmrInterPartCopy pointer

[Top]

Make the Copy

Retrieve the CATMmrInterPartCopy Interface pointer

The CreateMmiInterPartCopy method of CATMmiPubServicesAccess is used to creates a pointer on a

CATMmrInterPartCopy enabling to

copy geometry.

...

CATMmrInterPartCopy* pInterPartCopy = NULL;

rc = CATMmiPubServicesAccess::CreateMmiInterPartCopy(pInterPartCopy);

...

|

Set information relevant for feature copy

The process of actually copying a feature, is twofold. Initially we set the relevant information, essential for the copying operation. This is followed by the actual copy process.

The CreateMmiInterPartCopy Interface has a set of

APIs, illustrated in the code below, for setting these copy parameters.

...

CATBaseUnknown_var spTargetPart = spSpecObjectOnMechPartOfRepFeatCopied;

CATBoolean CopyWithLink = TRUE;

pInterPartCopy->SetObject(spFeatureToCopy);

pInterPartCopy->SetTarget(spTargetPart);

pInterPartCopy->SetProducts(spPLMProductOnInstChild1,spPLMProductOnInstChild2 );

pInterPartCopy->SetLinkMode(CopyWithLink) ;

...

|

SetObject and SetTarget are used to set the source object and target feature for

copying.

SetProducts is used to set the source and target

products context, it works only in case of copying in assembly context.

Here SetLinkMode (CopyWithLink is

TRUE) is used to Keep the link between source object and destination

object, to reflect the changes in geometry. CopyWithLink should

be TRUE as it is mandatory to create Mechanical Import.

Using GUID to be kept by the Mechanical Import

...

pInterPartCopy->SetImportApplicativeId(CAAMmrGUIDForApplicativeImport);

...

|

SetImportApplicativeId uses

GUID and sets an applicative identifier on the created

Mechanical Import, this method must be called before the Run

method. The

application which produces the copied feature can expose one special

identifier which is GUID. This identifier get associated with copied

feature at the time of copying. And this association is done by

SetImportApplicativeId.

Copy feature to target part

...

CATISpecObject_var ResultCopyAssm ;

pInterPartCopy->Run(ResultCopyAssm );

...

|

After setting all related information like source,

target and other parameters in CATMmrInterPartCopy object (i.e.

pInterPartCopy in this example), its time to call Run method. This will compute

the copy according to the specified inputs and the result will return in

ResultCopyAssm.

[Top]

Retrieve information from the copied feature using CATIMmiMechanicalImportApplicative

Retrieve the CATIMmiMechanicalImportApplicative*

type on the copied feature. The CATIMmiMechanicalImportApplicative

Interface exposes CAA services to enable us retrieve

information of the source feature from the copied feature.

..

CATIMmiMechanicalImportApplicative *pIMecImportApplicativeOnResultCopy = NULL ;

rc = ResultCopyAssm ->QueryInterface(IID_CATIMmiMechanicalImportApplicative,

(void**)&pIMecImportApplicativeOnResultCopy);

...

|

Before we proceed to seek the relevant information from

the copied feature, it is mandatory that we specify the Applicative

Identifier (GUID), (associated with the Mechanical Import, in an earlier

step) to the retrieval mechanism.

The following extract of code, illustrates the failure to retrieve information, in the absence of proper authorization. Once proper authorization is set, the calls which retrieve the information return SUCCESS.

...

CATBaseUnknown_var spPointedElement1 ;

rc = pIMecImportApplicativeOnResultCopy->GetPointedElement(spPointedElement1 );

if (SUCCEEDED(rc))//It should fail

return 1;

rc = pIMecImportApplicativeOnResultCopy->SetApplicativeId(CAAMmrGUIDForApplicativeImport);

rc = pIMecImportApplicativeOnResultCopy->GetPointedElement(spPointedElement1 );

...

|

GetPointedElement returns a

pointer to the pointed element. It may be a sub-element or a feature.

Before setting the applicativeId the GetPointedElement method

should fail.

SetApplicativeId is used to

set the applicative identifier. You have to give here the identifier of

the mechanical import. If you don't give the correct identifier, all

methods of this interface will fail.

After setting the ApplicativeId you will be authorized

to retrieve the information from the feature and this case your

GetPointedElement will work.

We now proceed to seek other relevant information from the copied feature.

...

CATBoolean LoadedPointedReference ;

rc = pIMecImportApplicativeOnResultCopy->IsPointedElementLoaded(LoadedPointedReference);

CATBaseUnknown_var spSourceProductInstance1;

pIMecImportApplicativeOnResultCopy->GetSourceProduct(spSourceProductInstance1);

... |

IsPointedElementLoaded gives the loading

status of the pointed representation.

GetSourceProduct

retrieve the Product Instance aggregating the Part document of the

Source Feature. And the function will product instance in

spSourceProductInstance1, this happens only in case of

copy in assembly context. But in case of copy without assembly context

method should have to fail. In copying feature for without assembly

context you can only retrieve the original feature, no product instance.

[Top]

Reset the CATIMmiInterPartCopy pointer

After every confirmation of result we should have to

reset the CATMmrInterPartCopy pointer for next

copy.

...

pInterPartCopy->Reset();

...

|

[Top]

In Short

The Use Case creates a Mechanical Import, an end result

of copying a feature, with the Link mode set to

TRUE. A Mechanical Import implements the CATIMmiMechanicalImportApplicative

Interface, which

enables us to retrieve relevant information of the source feature from

its copied entity.

The process of actually retrieving this information

needs proper authorization. The Use Case illustrates the failure to

retrieve information, in the absence of proper authorization and details

the steps involved in generating a GUID (Applicative ID) and specifying

it to the copying process, so that it associates it with the Mechanical

Import.

Finally, this GUID is specified to the retrieving

mechanism, which authorizes us to retrieve the source feature, its

aggregating Product Instance and its load status.

[Top]

References

| [1] | Managing Applicative Mechanical Imports |

| [2] | About Globally Unique Identifiers |

| [3] | Copying Mechanical Features |

| [4] | Building and Launching a CAA V5 Use Case |

[Top]

History

| Version: 1 [July 2007] | Document created |

| [Top] | |

Copyright © 2007, Dassault Systèmes. All rights reserved.