Mechanical Modeler |

|

Copying Mechanical FeaturesUsing CATMmrInterPartCopy |

| Use Case | ||

AbstractThis article shows how to copy mechanical features using CATMmrInterPartCopy. |

This use case explains the usage of the CATMmrInterPartCopy to copy mechanical features. Its presents:

In the What Does CAAMmrInterIntraPartCopy Do section, all the copies done by the code are presented by pictures, and commented. It gives you an overview of the CATMmrInterPartCopy possibilities, and the result of the copies.

[Top]

CAAMmrInterIntraPartCopy is a use case of the CAAMechanicalModeler.edu framework that illustrates MechanicalModeler framework capabilities.

[Top]

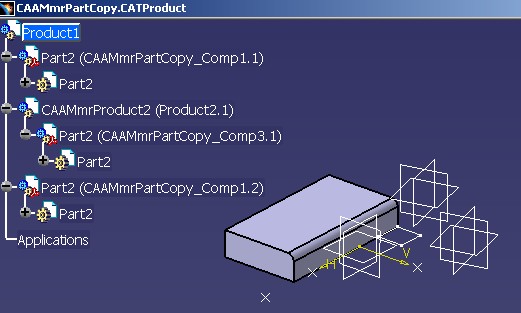

This use case uses a Product document containing instances of Part documents.

|

The CAAMmrPartCopy document contains one of the CAAMmrPartCopy_Comp3

Part

document, and two instances of the

CAAMmrPartCopy_Comp1 Part document.

|

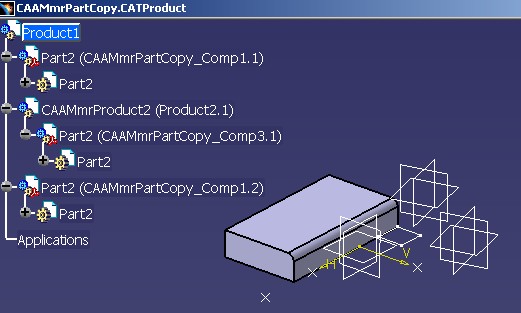

The

CAAMmrPartCopy_Comp1 document only contains geometrical features sets [2].

|

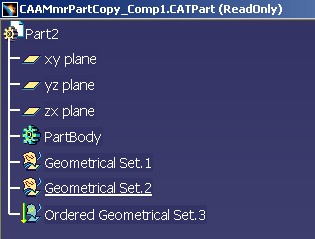

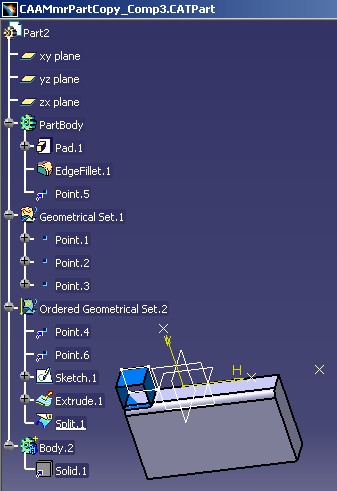

The

CAAMmrPartCopy_Comp3 document contains some points, one pad, and an

invisible surface

(an extruded sketch which is splitted: the result is not visible because Split.1 is not the

current feature. Refer to the article entitled "Order and Absorption Concept [3]).

These four documents, the two Part documents and the two Product

documents are located in the InputData directory of the

CAAMechanicalModeler.edu framework.

The batch carries out a series of copies between mechanical features:

From CAAMmrPartCopy_Comp3 to

CAAMmrPartCopy_Comp1

Source (CAAMmrPartCopy_Comp3) |

Target (CAAMmrPartCopy_Comp1) |

PartBody |

Part |

Point.1 |

Part |

Point.2 |

PartBody |

Point.3 |

Geometrical Set.1 |

Geometrical Set.1 |

Part |

Ordered Geometrical Set.2 |

PartBody |

Ordered Geometrical Set.2 |

Ordered Geometrical Set.3 |

These copies are done with four alternatives:

Note that the copies out of Assembly context, are equivalent to open separately the two Part documents, and to do the copies.

From CAAMmrPartCopy_Comp3 to CAAMmrPartCopy_Comp3

Source (CAAMmrPartCopy_Comp3) |

Target (CAAMmrPartCopy_Comp3) |

PartBody |

Part |

Point.1 |

Part |

Point.2 |

PartBody |

Point.3 |

Ordered Geometrical Set.2 |

These copies are done with two alternatives:

Now the result of these copies are presenting according to the different alternatives.

It consists to copy mechanical features from CAAMmrPartCopy_Comp3

to CAAMmrPartCopy_Comp1.

|

Copy As Result With Link |

Copy As Result |

|

|

|

These two images show the CAAMmrPartCopy_Comp1

after the copies. The four existing sets of this Part document are surrounded in

yellow.

First considerations:

It means that the geometry is copied, but in case of original feature

modification, the copied result can be updated. Note that some

icons (![]() ,

,![]() ) have the ? symbol. This

symbol means that

the original document is not opened. If the original document is opened, here

the

) have the ? symbol. This

symbol means that

the original document is not opened. If the original document is opened, here

the CAAMmrPartCopy_Comp3 Part document, the

same icons becomes (![]() ,

, ![]() ).

If you change the coordinates of a point in the original document, the icon of the copied feature becomes :

).

If you change the coordinates of a point in the original document, the icon of the copied feature becomes :

![]() . To synchronize the copied feature, either the synchronization is automatically

done in the update ( See Tools options), or you explicitly synchronize

the feature using the Synchronize command.

. To synchronize the copied feature, either the synchronization is automatically

done in the update ( See Tools options), or you explicitly synchronize

the feature using the Synchronize command.

It means that the geometry is copied, but in case of original feature modification, the copied result will be never updated.

Note that the same icons are now:

and

.

PartBody, from CAAMmrPartCopy_Comp3,

copied into the Part of CAAMmrPartCopy_Comp1 is

Body.2

Point.1, from CAAMmrPartCopy_Comp3,copied into the Part of CAAMmrPartCopy_Comp1 is

Point.1.

On the left, Point.1

is located under the

External References feature, the mechanical feature which groups together

the external references.

On the right, Point.1 is a datum [4]. It is aggregated under

Geometrical Set.2, the current geometrical feature set of

CAAMmrPartCopy_Comp1 - Note

that Geometrical Set.2 is underlined.

Point.2, from CAAMmrPartCopy_Comp3,copied into the PartBody of CAAMmrPartCopy_Comp1 is

Point.2. From R14, It is possible to insert a surfacic feature into a Body

feature.

Point.3, from CAAMmrPartCopy_Comp3,

copied into Geometrical Set.1 of CAAMmrPartCopy_Comp1

is Point.3

Geometrical Set.1, from CAAMmrPartCopy_Comp3,

copied into the Part feature of CAAMmrPartCopy_Comp1

is on left, Geometrical Set.5, and on right, Geometrical

Set.4. This difference comes from that on left, External References has

been created. Except, this naming's difference, you can note that both contain

datum features. The contents of Geometrical Set.1 has been copied

with the "As result" option in the two cases. In a future version, the "As Result

With link" for a geometrical features set will be possible. Note that today,

interactively this kind of copy is impossible.

Ordered Geometrical Set.2, from

CAAMmrPartCopy_Comp3, copied

into the PartBody of CAAMmrPartCopy_Comp1 is Ordered Geometrical

Set.6.

On the left, and on the right the same icon:

![]() - It is the same problem as for

- It is the same problem as for Geometrical Set.1. Whatever the

copy option, the contents of an Ordered Geometrical Set is

copied with the "As Result" option.

Sketch.2 included into Ordered Geometrical

Set.2 is not copied. Sketches are never copied such as interactively.

Extrude.1 is not copied, Surface.2

is the "result" of Split.1, an absorbent feature. [3].

Ordered Geometrical Set.2, from

CAAMmrPartCopy_Comp3, copied into the

Ordered Geometrical Set.3 of

CAAMmrPartCopy_Comp1 is

Ordered Geometrical Set.7

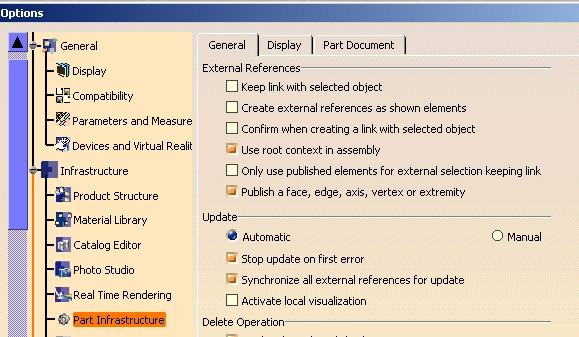

It is always the same copies from CAAMmrPartCopy_Comp3

to CAAMmrPartCopy_Comp1, but now in Assembly context.

|

Copy As Result with link |

Copy As Result |

|

|

|

These two images show the CAAMmrPartCopy document

after the copies. The four existing sets of this Part document are surrounded in

yellow.

First considerations are about the Product's icons.

The Part origin of the features is the

CAAMmrPartCopy_Comp3 document. They are copied in an instance of the

CAAMmrPartCopy_Comp1 Part document. (CAAMmrPartCopy_Comp1.1). So

sometimes, you can also read Ref/Inst copies.

Before the copy, on the [Fig.1] you can see

the following icons before each Product instance:

![]()

After the copy, and in copy "As Result", the icons are always

![]() .

.

But in case of "As Result with link" copy option, the icons

become

![]() before

before CAAMmrPartCopy_Comp1.1, and

![]()

before CAAMmrPartCopy_Comp1.2.

Second considerations are about the copies's location.

You can see on [Fig.5] that two results are

coincident: The yellow pad (from CAAMmrPartCopy_Comp1.1) and the grey

one (from CAAMmrPartCopy_Comp3) are coincident. On the Product

instance links to CAAMmrPartCopy_Comp1.1, a positioning matrix, computed from the matrix of CAAMmrPartCopy_Comp3

and CAAMmrPartCopy_Comp1.1, is stored.

Otherwise, about the result of the copies with (on the left), or without link (on the right) it is the same comments as for copies without Assembly context ([Fig.4]).

In this last case, copies are done from and to the CAAMmrPartCopy_Comp3

Part document.

|

Copy As Result with link |

Copy As Result |

|

|

These two images show the CAAMmrPartCopy_Comp3 Part document

after the copies.

First considerations:

On the left, the "As result with link" copies.

See the icons:

![]() for the solid, and

for the solid, and

![]() for the points. It means that the geometry has been copied with the "As result

with link" option within the Part document.

for the points. It means that the geometry has been copied with the "As result

with link" option within the Part document.

On the right, the "As result" (without link)

copies. The same icons are now the icons representing a datum:

![]() and

and

![]() .

.

About the copies themself:

Body.1 is the copy of PartBody. The

geometry are of course at the same location.

Point.4 is the copy of Point.1. The

Part feature being the destination, Point.4 is

included before the current feature of Ordered Geometrical Set.2.

On [Fig.3] you can see that Sketch.1 is the

current feature. So the new point is created just before it [3].

( Point.6 will be created after)

Point.5 is the copy of Point.2.

PartBody being the destination, Point.4 is included in the

Body feature, like it is possible since the V5R14 level.

Point.6 is the copy of Point.3. Such

as Point.4, the new point is created before Sketch.1

into Ordered Geometrical Set.2

To launch CAAMmrInterIntraPartCopy, you will need to set up the build time environment, then compile CAAMmrInterIntraPartCopy along with its prerequisites, set up the run time environment, and then execute the use case [5]. To launch the use case, execute the following steps:

CAAMmrPartCopy_Comp3.CATPart,

CAAMmrPartCopy_Comp1.CATPart,

CAAMmrPartCopy.CATProduct, CAAMmrProduct2.CATProductThey are located in the CAAMechanicalModeler.edu/InputData

directory

InstallRootDirectory/CAAMechanicalModeler.edu/InputData

InstallRootDirectory\CAAMechanicalModeler.edu\InputData

mkrun -c "CAAMmrInterIntraPartCopy InputPath Copy_Option PS_Option "

where

The input documents, those of your directory, are modified, and contain the result of the copies.

Some examples:

To copy the mechanical features, out of the Assembly context, and with "As Result with link" option. See the results, Fig.4 and Fig.6, both on the left

To copy the mechanical features, out of the Assembly context, and with "As Result" option. See the results, Fig.4 and Fig.6, both on the right

To copy the mechanical features, in Assembly context, and with "As Result with link" option. See the results, Fig.5, on the left

To copy the mechanical features, in Assembly context, and with "As Result" option. See the results, Fig.5, on the right

[Top]

The CAAMmrInterIntraPartCopy use case is made of a single source file named CAAMmrInterIntraPartCopyMain.cpp located in the CAAMmrInterIntraPartCopy.m module of the CAAMechanicalModeler.edu framework

| Windows | InstallRootDirectory\CAAMechanicalModeler.edu\CAAMmrInterIntraPartCopy.m\ |

| Unix | InstallRootDirectory/CAAMechanicalModeler.edu/CAAMmrInterIntraPartCopy.m/ |

The use case uses two global functions, CAAMmrGetGeometry and CAAMmrGetPartFromProduct, which are defined in the following directory:

| Windows | InstallRootDirectory\CAAMechanicalModeler.edu\CAAMmrUtilities.m\ |

| Unix | InstallRootDirectory/CAAMechanicalModeler.edu/CAAMmrUtilities.m/ |

where InstallRootDirectory is the directory where the CAA CD-ROM

is installed.

[Top]

There are five logical steps in CAAMmrInterIntraPartCopy:

All the copies shown in the "What Does CAAMmrInterIntraPartCopy Do" section are not there detailed. Only two of them are given to explain the usage of the CATMmrInterPartCopy class.

[Top]

CAAMmrInterIntraPartCopy begins by creating a session, and opening the input

Product document. Next it retrieves all the Product components begining with its

root product,piProductOnRoot. This is the usual sequence for loading a Product document [6].

... CATListValCATBaseUnknown_var * pListDirectChildren = piProductOnRoot->GetChildren(); // Comp1 and Comp2 CATIProduct_var spComp1 = (*pListDirectChildren)[1] ; CATIProduct_var spComp2 = (*pListDirectChildren)[2] ; delete pListDirectChildren ; pListDirectChildren = NULL ; pListDirectChildren = spComp2->GetChildren(); // Comp3 CATIProduct_var spComp3 = (*pListDirectChildren)[1] ; ... |

From the two Product documents, spComp1 and spComp3,

their MechanicalPart feature is retrieved thanks the

CAAMmrGetPartFromProduct global function. Once the Part feature is retrieved, the useful mechanical features

are retrieved using the CAAMmrGetGeometry global function. The contents

of these two global functions being not

essential for the use case, the code is not detailed here; refer to the source

files otherwise.

[Top]

The copy of Point.3 (CAAMmrPartCopy_Comp3) into

Ordered Geometrical Set.2 (CAAMmrPartCopy_Comp3) is detailed. The new

feature

is Point.6. You can see the result on the [Fig.6].

The copy is done with five steps.

... CATISpecObject_var SourceToCopy = spOnPoint3OfComp3 ; CATISpecObject_var Target = spOnOrderedGeomSet2OfComp3 ; CATMmrInterPartCopy * ptCATMmrInterPartCopy = new CATMmrInterPartCopy (SourceToCopy,Target) ; ... |

spOnPoint3OfComp3 and spOnOrderedGeomSet2OfComp3

are smart pointers on Point.3 and Ordered Geometrical Set.2,

two mechanical features of the

CAAMmrPartCopy_Comp3 Part document See [Fig.3].

Refer to the code of the use case, the way to retrieve these two pointers.

SetLinkMode method.

... ptCATMmrInterPartCopy ->SetLinkMode(CopyWithLink); ... |

CopyWithLink is a CATBoolean value. It is valuated according to

the Copy_Option argument of the program. See the How to Launch CAAMmrInterIntraPartCopy

section. If the argument is 1, the value of CopyWithLink is TRUE, otherwise its value is FALSE. If you do not use the

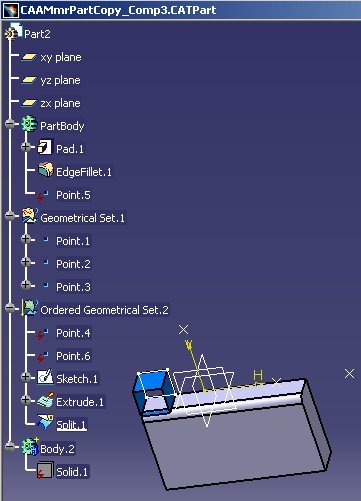

SetLinkMode method, the option of copy depends on the "Keep link with

selected object" option.

|

Run method.

... ErrorMsg = "" ; rc = ptCATMmrInterPartCopy ->Run(&ErrorMsg); ... |

GetResult

method.

...

rc = ptCATMmrInterPartCopy ->GetResult(Result);

if ( SUCCEEDED(rc) && (NULL_var != Result) )

{

CATIAlias_var spAlias = Result ;

if ( NULL_var != spAlias )

{

cout <<" The result of the copy is" ;

cout <<" " << spAlias->GetAlias().CastToCharPtr() << endl << endl;

}

...

|

This step is of course optional.

... delete ptCATMmrInterPartCopy ; ptCATMmrInterPartCopy = NULL ; |

To copy another mechanical feature you must come back to the first step.

[Top]

The copy of Point.1 of CAAMmrPartCopy_Comp3 into

the Part feature of CAAMmrPartCopy_Comp1.1 is detailed. The new

feature is Point.1. You can the result on the [Fig.4].

These copy is done with six steps.

CATISpecObject_var SourceToCopy = spOnPoint1OfComp3 ;

CATISpecObject_var Target = spSpecObjectOnMechPartOfComp1;

CATMmrInterPartCopy * ptCATMmrInterPartCopy = new CATMmrInterPartCopy (SourceToCopy,Target) ;

...

|

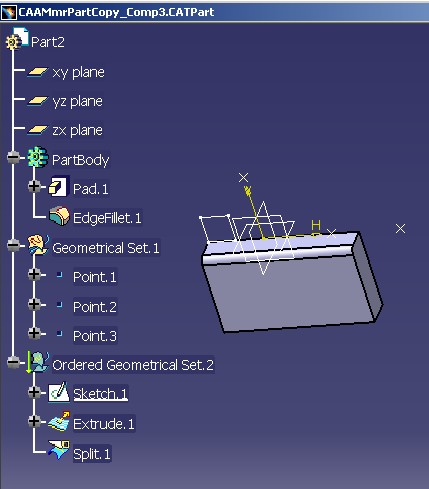

spOnPoint1OfComp3 is a smart pointer on Point.1 of

the CAAMmrPartCopy_Comp3 document [Fig.3].

spSpecObjectOnMechPartOfComp1 is a smart pointer on the Part

feature of the CAAMmrPartCopy_Comp1 document [Fig.2].

Refer to the code of the use case, the way to retrieve these two pointers.

SetLinkMode method.

... ptCATMmrInterPartCopy ->SetLinkMode(CopyWithLink); ... |

CopyWithLink is a CATBoolean value. It is valuated according to

the Copy_Option argument of the program. See the How to Launch CAAMmrInterIntraPartCopy

section. If the argument is 1, the value of CopyWithLink is TRUE, otherwise its value is FALSE. If you do not use the

SetLinkMode method, the option of copy depends on the "Keep link with

selected object" option. See [Fig.7]

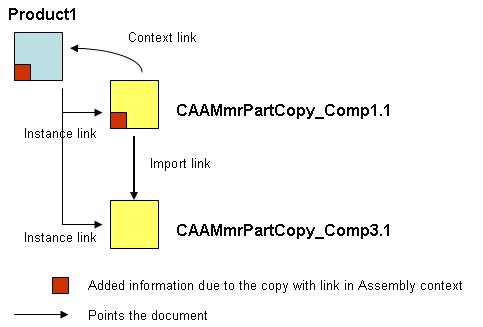

Until then, no difference with the previous copy. But if you use

SetSourceInstance, and the SetTargetInstance you are in

Assembly context.

... ptCATMmrInterPartCopy ->SetSourceInstance(spComp3); ptCATMmrInterPartCopy ->SetTargetInstance(spComp1); ... |

spComp3 and spComp1

are smart pointers on a CATIProduct

interface retrieved in the prolog step. spComp3 is a pointer on the

CAAMmrPartCopy_Comp3 Product instance, and

spComp1 pointer on the CAAMmrPartCopy_Comp1.1

Product instance

![]()

If you do not specify the product context, so if you do not use these two methods, you are copying features without Assembly context. So it is the result that you can see on the [Fig.4].

Run method.

... ErrorMsg = "" ; rc = ptCATMmrInterPartCopy ->Run(&ErrorMsg); ... |

GetResult

method.

... rc = ptCATMmrInterPartCopy ->GetResult(Result); ... |

This step is of course facultative.

... delete ptCATMmrInterPartCopy ; ptCATMmrInterPartCopy = NULL ; |

To copy another mechanical feature you must come back to the first step.

The four modified documents:

CAAMmrPartCopy_Comp3.CATPart, CAAMmrPartCopy_Comp1.CATPart, CAAMmrPartCopy.CATProduct

and

CAAMmrProduct2.CATProduct are saved using the SaveAs method

of the CATDocumentServices class.

|

If you first save the Product with another name, the saved document pointes to Comp1.1 which will be after saved under another name

If you first save Comp1.1 with another name, the saved document pointes to Product1 which will be after saved under another name

Save method which does not work in batch mode.[Top]

All the documents are removed from the session using the Remove method

of the CATDocumentServices class, and then the session is closed using

the global function named Delete_Session.

[Top]

This use case has shown different kind of copies, and explained the usage of the CATMmrInterPartCopy class.

[Top]

| Version: 1 [Oct 2004] | Document created |

| [Top] | |

Copyright © 2004, Dassault Systèmes. All rights reserved.