Machining |

Machining Algorithms |

Multi-axis Machining AlgorithmsCreating points with multi-axis machining algorithms |

| Use Case | ||

AbstractThis article discusses the CAASmaMultiAxisAlgorithms use case and explains how to use multi-axis machining algorithms. |

This use case is intended to help you run multi-axis machining algorithms. Its main intent is to explain how to set parameters, compute and read results of machining algorithms, which are:

[Top]

CAASmaMultiAxisAlgorithms is a use case of the CAASurfaceMachiningAlgoItf.edu framework that illustrates the SurfaceMachiningAlgoInterfaces framework capabilities.

[Top]

CAASmaMultiAxisAlgorithms creates geometrical points, that follow tool paths computed by multi-axis sweeping and multi-axis contour driven algorithms.

|

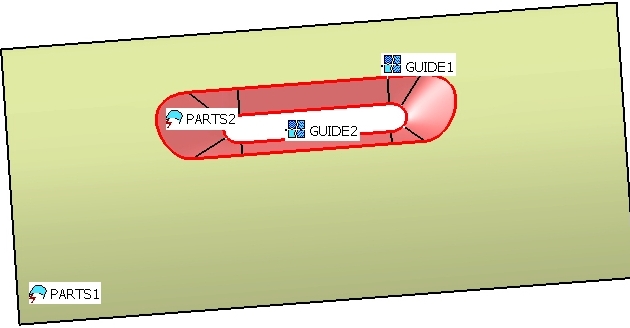

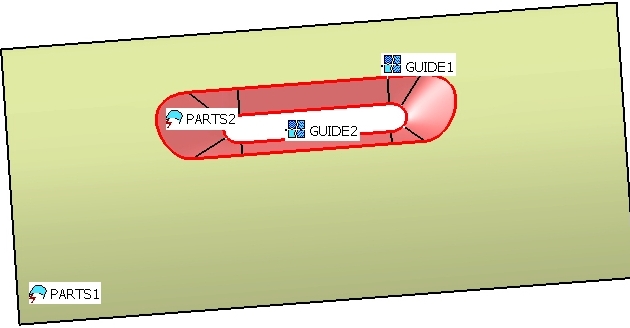

It opens a Part document, finds the first geometrical set and retrieves geometry of PARTS1, PARTS2, GUIDE1 and GUIDE2. |

|

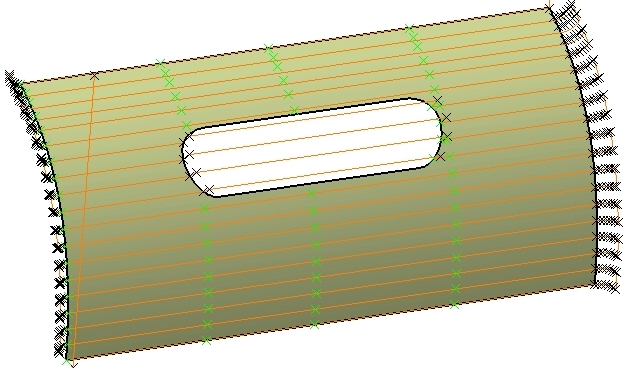

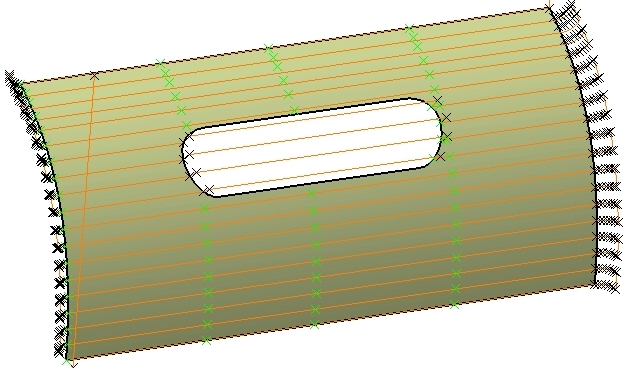

It runs a multi-axis sweeping algorithm on PARTS1 and creates a first set of points (points lying on the surface are green). |

|

It runs a multi-axis contour driven algorithm on PARTS2 between GUIDE1 and GUIDE2 and creates a second set of points. |

[Top]

To launch CAASmaMultiAxisAlgorithms, you will need to set up the build time environment, then compile CAASmaMultiAxisAlgorithms along with its prerequisites, set up the run time environment, and then execute the use case [1].

To launch the use case, execute the following command:

mkrun -c "CAASmaMultiAxisAlgorithms Filename"

where Filename is the path of a Part document. You can use the CAAMultiAxisAlgorithms.CATPart

located:

| Unix | InstallRootDirectory/CAASurfaceMachiningAlgoItf.edu/InputData |

| Windows | InstallRootDirectory\CAASurfaceMachiningAlgoItf.edu\InputData |

[Top]

The use case code is located in the CAASmaMultiAxisAlgorithms.m module of the CAASurfaceMachiningAlgoItf.edu framework:

| Windows | InstallRootDirectory\CAASurfaceMachiningAlgoItf.edu\CAASmaMultiAxisAlgorithms.m |

| Unix | InstallRootDirectory/CAASurfaceMachiningAlgoItf.edu/CAASmaMultiAxisAlgorithms.m |

where InstallRootDirectory is the directory where the CAA CD-ROM

is installed.

[Top]

There are five logical steps in CAASmaMultiAxisAlgorithms:

We will now comment each of those sections by looking at the code.

[Top]

First, we need to get geometries used by machining algorithms.

CATDocument *pPartDoc = NULL;

rc = CATDocumentServices::OpenDocument(InputPathName, pPartDoc);

...

CATIPartRequest_var spPartRequest(spPart);

if (NULL_var != spPartRequest)

{

CATListValCATBaseUnknown_var ListOfSurfacicSets;

spPartRequest->GetSurfBodies(CATUnicodeString (""), ListOfSurfacicSets);

...

|

The CATDocumentServices::OpenDocument static method opens the part

document from the location given as first argument of the main program. From the

root container of the part, we get the CATIPartRequest interface and use

it to access to the first geometrical set of the part.

CATIDescendants_var spDescOnSurfacicSet = ListOfSurfacicSets[1];

if (NULL_var != spDescOnSurfacicSet)

{

CATListValCATISpecObject_var ListOfGeometricalElts;

spDescOnSurfacicSet->GetDirectChildren(CATIGeometricalElement::ClassName(), ListOfGeometricalElts);

...

for (int ig=1;ig<=NbGeometricalElts;ig++)

{

CATIGeometricalElement_var spGeomElement = ListOfGeometricalElts[ig];

if (NULL_var != spGeomElement)

{

CATBody_var spBody = spGeomElement->GetBodyResult();

...

|

We scan its children features thanks to GetDirectChildren, and get

the topological result with GetBodyResult.

spBody->GetAllCells(ListOfCells,2);

for (int i=1;i<=NbCells;i++)

{

CATFace_var spFace = ListOfCells[i];

if (NULL_var != spFace)

{

if (0 != IsParts1) ListOfParts1.Append(spFace);

else ListOfParts2.Append(spFace);

...

|

From features called PARTS1 and PARTS2, we get the faces and fill the according

lists ListOfParts1 and ListOfParts2.

spBody->GetAllCells(ListOfCells,1);

for (int i=1;i<=NbCells;i++)

{

CATEdge_var spEdge = ListOfCells[i];

if (NULL_var != spEdge)

{

CATEdgeCurve * pEdgeCurve = spEdge->GetCurve();

CATCurve_var spCurve = pEdgeCurve;

if (NULL_var != spCurve)

{

if (0 != IsGuide1) ListOfGuide1.Append(spCurve);

else ListOfGuide2.Append(spCurve);

...

|

From features called GUIDE1 and GUIDE2, we get the curves and fill the according

lists ListOfGuide1 and ListOfGuide2.

[Top]

To store algorithms results, we need to get a machining tool path container.

CATDocument *pProcessDoc = NULL;

rc = CATDocumentServices::New("Process", pProcessDoc );

...

CATIMfgMachiningContainer * piMfgEnvt = NULL;

piProcessContainer->QueryInterface(CATIMfgMachiningContainer::ClassId(), (void**)&piMfgEnvt);

if (piMfgEnvt)

{

piMfgEnvt->InitContainer(FALSE,0);

...

}

CATIContainer_var spTPContainer;

CATIMfgManufacturingFactories *piFact =NULL;

CATString ClassName("CATMfgManufacturingFactories");

::CATInstantiateComponent (ClassName, CATIMfgManufacturingFactories::ClassId(), (void**)& piFact);

if (piFact)

{

piFact->GetManufacturingToolPathFactory(spTPContainer);

...

|

The CATDocumentServices::OpenDocument static method creates a process

document. From the root container of the process, we initialize the machining containers

with InitContainer and we get the tool path container thanks to the

CATIMfgManufacturingFactories interface.

[Top]

CATIMfgMultiAxisAlgorithm *piMMSweepingAlgo =NULL;

::CATInstantiateComponent ("CATMfgAlgoMultiAxisSweeping", CATIMfgMultiAxisAlgorithm::ClassId(), (void**)& piMMSweepingAlgo);

...

rc = piMMSweepingAlgo->SetValue(MfgAlgMachiningTolerance,0.1); // Machining tolerance

rc = piMMSweepingAlgo->SetValue(MfgAlgMaxDiscretizationStep,100.); // Maximum discretization step

rc = piMMSweepingAlgo->SetValue(MfgAlgMaxDistance,10.); // Distance on part

rc = piMMSweepingAlgo->SetDirection(MfgAlgViewDirection,XVector); // View dir

rc = piMMSweepingAlgo->SetDirection(MfgAlgStartDirection,YVector); // Start dir

rc = piMMSweepingAlgo->SetSurfacicGeometry(MfgAlgParts,ListOfParts1); // Parts

rc = piMMSweepingAlgo->AddMacroSyntax(1,"START"); // Approach macro

rc = piMMSweepingAlgo->AddMacroTangentMotion(1,10.,90.,0.);

rc = piMMSweepingAlgo->AddMacroToAPlaneMotion(1,MacroPlane);

rc = piMMSweepingAlgo->AddMacroSyntax(2,"END"); // Retract macro

rc = piMMSweepingAlgo->AddMacroToAPlaneMotion(2,MacroPlane);

rc = piMMSweepingAlgo->AddMacroSyntax(3,"START"); // Linking Approach macro

rc = piMMSweepingAlgo->AddMacroAxialMotion(3);

rc = piMMSweepingAlgo->AddMacroSyntax(4,"END"); // Linking Retract macro

rc = piMMSweepingAlgo->AddMacroAxialMotion(4);

rc = piMMSweepingAlgo->AddMacroSyntax(5,"START"); // Return in a level Approach macro

rc = piMMSweepingAlgo->AddMacroCircularMotion(5,90.,90.,10.);

rc = piMMSweepingAlgo->AddMacroSyntax(6,"END"); // Return in a level Retract macro

rc = piMMSweepingAlgo->AddMacroCircularMotion(6,90.,90.,10.);

...

CATBaseUnknown_var spSweepingTP;

rc = piMMSweepingAlgo->ComputeToolPath(spTPContainer,spSweepingTP);

|

First we create an instance of the multi-axis sweeping algorithm with the

CATInstantiateComponent global function, the instance name is "CATMfgAlgoMultiAxisSweeping",

we can also use MultiAxisSweepingInstanceName constant. Then we set parameters trough

the CATIMfgMultiAxisAlgorithm interface.

SetValue method is used to set the following numerical parameters:

MfgAlgMachiningTolerance: Machining tolerance, it is the maximum

allowed distance between the theoretical and computed tool pathMfgAlgMaxDiscretizationStep: Maximum discretization step, it

ensures linearity between points that are far apartMfgAlgMaxDiscretizationAngle: Maximum discretization angle,

it specifies the maximum angular change of tool axis between tool positionsMfgAlgMaxDistance: Distance on part, it defines the maximum

distance between two consecutive tool pathsMfgAlgMachiningMode: Tool path style, the cutting mode is one

way or zigzagMfgAlgStepoverSide: Stepover side, it determines the side of

the machining directionSetDirection method sets a direction:

MfgAlgViewDirection: View directionMfgAlgStartDirection: Start directionSetSurfacicGeometry method sets the geometry of the parts. The call

of this method is mandatory.

Macros motions are defined by one or several elementary motions with the following methods:

AddMacroAxialMotion: along the tool axisAddMacroTangentMotion: tangent at its end to the tool path

AddMacroRampingMotion: following a slope AddMacroCircularMotion: in a arcAddMacroToAPlaneMotion: up to a plane AddMacroAlongALineMotion: along a vector AddMacroSyntax: insert a user syntax SetTool method sets a manufacturing tool. If we don't call it, then

a default ball end tool will be used during computation.

At last, ComputeToolPath creates and returns a tool path. It is

created in the container pointed by spTPContainer.

[Top]

CATIMfgMultiAxisAlgorithm *piMMContourDriven =NULL;

::CATInstantiateComponent ("CATMfgAlgoMultiAxisContourDriven", CATIMfgMultiAxisAlgorithm::ClassId(), (void**)& piMMContourDriven);

...

rc = piMMContourDriven->SetValue(MfgAlgMachiningTolerance,0.1); // Machining tolerance

rc = piMMContourDriven->SetValue(MfgAlgMaxDistance,10.); // Distance on part

rc = piMMContourDriven->SetValue(MfgAlgOffsetOnGuide1,-1.); // Offset on guide 1

rc = piMMContourDriven->SetValue(MfgAlgOffsetOnGuide2,-1.); // Offset on guide 2

rc = piMMContourDriven->SetValue(MfgAlgContouringMode,1); // Between Contour guiding strategy

rc = piMMContourDriven->SetValue(MfgAlgMachiningMode,1); // One-way tool path style

CATMathVector NormalView(2.,0.,1.);

rc = piMMContourDriven->SetDirection(MfgAlgViewDirection,NormalView); // View dir

rc = piMMContourDriven->SetDirection(MfgAlgStartDirection,YVector); // Start dir

rc = piMMContourDriven->SetSurfacicGeometry(MfgAlgParts,ListOfParts2); // Parts

rc = piMMContourDriven->SetWireFrameGeometry(MfgAlgGuide1,ListOfGuide1); // First guide

rc = piMMContourDriven->SetWireFrameGeometry(MfgAlgGuide2,ListOfGuide2); // Second guide

rc = piMMContourDriven->AddMacroSyntax(1,"START"); // Approach macro

rc = piMMContourDriven->AddMacroTangentMotion(1,10.,90.,0.);

rc = piMMContourDriven->AddMacroToAPlaneMotion(1,MacroPlane);

rc = piMMContourDriven->AddMacroSyntax(2,"END"); // Retract macro

rc = piMMContourDriven->AddMacroTangentMotion(2,10.,90.,0.);

rc = piMMContourDriven->AddMacroToAPlaneMotion(2,MacroPlane);

...

CATBaseUnknown_var spContourDrivenTP;

rc = piMMContourDriven->ComputeToolPath(spTPContainer,spContourDrivenTP);

|

First we create an instance of the multi-axis contour driven algorithm with the

CATInstantiateComponent global function, the instance name is "CATMfgAlgoMultiAxisContourDriven",

we can also use MultiAxisContourDrivenInstanceName constant. Then we set parameters trough

the CATIMfgMultiAxisAlgorithm interface.

SetValue method sets numerical parameters. All parameters of multi-axis

sweeping are available for multi-axis contour driven. Additional parameters are:

MfgAlgOffsetOnGuide1: Offset on guide 1MfgAlgOffsetOnGuide2: Offset on guide 2MfgAlgPositionOnGuide1: Position with respect to the guide

1MfgAlgPositionOnGuide2: Position with respect to the guide

2MfgAlgContouringMode: Guiding strategy, it is between contours

or parallel contourMfgAlgFromToContour: Direction in parallel contour mode, it

starts from the guide or it is done up to the guideSetSurfacicGeometry method sets the geometry of the parts. The call

of this method is mandatory.

SetWireFrameGeometry method sets one of the following geometry:

MfgAlgGuide1: First guide, it is a mandatory geometryMfgAlgGuide2: Second guide, it is a mandatory geometry in between

contours modeMfgAlgStop1: First stop , it delimits the ends of pathsMfgAlgStop2: Second stop, it delimits the ends of pathsMfgAlgLimitLine: Limiting contour, it defines a limit to the

part surface and is also available for multi-axis sweeping algorithmDirection, tool and macro motions are defined like in the multi-axis sweeping algorithm.

At last, ComputeToolPath creates and returns a tool path. It is

created in the container pointed by spTPContainer.

[Top]

Finally we scan information of tool paths and create points in the part document.

...

CATIPrtContainer_var spPrtContainer = ispPartContainer;

if (NULL_var != spPrtContainer)

{

CATISpecObject_var spRootPart = spPrtContainer->GetPart();

spMechRootFactory->CreateGeometricalSet("",spRootPart,ospGeomSet);

}

...

CATIMfgTPMultipleMotion_var spMultipleMotion ((*pListOfMultipleMotion)[1]);

if (NULL_var != spMultipleMotion)

{

spMultipleMotion->GetNumberOfSubTrajects(NbSubTrajects);

for (int ia=1;ia<=NbSubTrajects;ia++)

{

CATIMfgTPMultipleMotion::SubTrajectType SubTrajectType;

spMultipleMotion->GetSubTrajectType(ia,SubTrajectType);

if (CATIMfgTPMultipleMotion::UserSyntax == SubTrajectType) // Syntax defined in macros

{

CATUnicodeString Syntax;

spMultipleMotion->GetUserSyntaxCharacteristics(ia,Syntax);

if (0 != Syntax.Compare("START")) GreenColor = 1;

else if (0 != Syntax.Compare("END")) GreenColor = 0;

}

else // Traject

{

int StartNumber =0, EndNumber =0;

spMultipleMotion->GetStartAndEndNumber(ia,StartNumber,EndNumber);

for (int ib=StartNumber;ib<=EndNumber;ib++)

{

double x=0.,y=0.,z=0.;

spMultipleMotion->GetTipPoint(ib,x,y,z);

double Coord [3] = {x,y,z};

CATIGSMPoint_var spGSMPoint = spGSMFactory->CreatePoint(Coord);

...

if (1 == GreenColor) // Points lying on parts will be green

{

CATIVisProperties_var spGraphicsPoint = spGSMPoint;

if (NULL_var != spGraphicsPoint)

{

CATVisPropertiesValues VisProperties;

VisProperties.SetColor(0, 255, 0); // Green color

spGraphicsPoint->SetPropertiesAtt(VisProperties, CATVPColor, CATVPPoint);

...

|

First we create a new geometrical set in the part container with CreateGeometricalSet

method. Then we get a pointer on CATIMfgTPMultipleMotion and we scan the

tool path. For each sub-trajects, we get the type with GetSubTrajectType

and the position of tool path points with GetTipPoint.

Points are created in the new geometrical set thanks to the CreatePoint

method of CATIGSMFactory interface.

With the help of "START" and "END" user syntax defined in macros motions, we know which points

are on the part surface and we colored them in green thanks to SetPropertiesAtt

method of CATIVisProperties interface.

[Top]

[Top]

| [1] | Building and Launching a CAA V5 Use Case |

| [Top] | |

| Version: 1 [Mar 2006] | Document created |

| [Top] | |

Copyright © 2006, Dassault Systèmes. All rights reserved.