Machining |

NC Review |

Customizing Tool Path Computation on Axial OperationsImplementing the CATIMfgComputeToolPathCustom interface |

| Use Case | ||

AbstractThis article discusses the CAAMaiToolPathCustomization use case and explains how to implement the CATIMfgComputeToolPathCustom manufacturing interface. |

This use case is intended to help you customize the tool path computation of a prismatic machining activity, namely an axial operation, by implementing the CATIMfgComputeToolPathCustom manufacturing interface. This involves the following:

ComputeToolPath method of CATIMfgComputeToolPathCustom

to:

[Top]

CAAMaiToolPathCustomization is a use case of the CAAManufacturingItf.edu framework that illustrates ManufacturingInterfaces framework capabilities.

[Top]

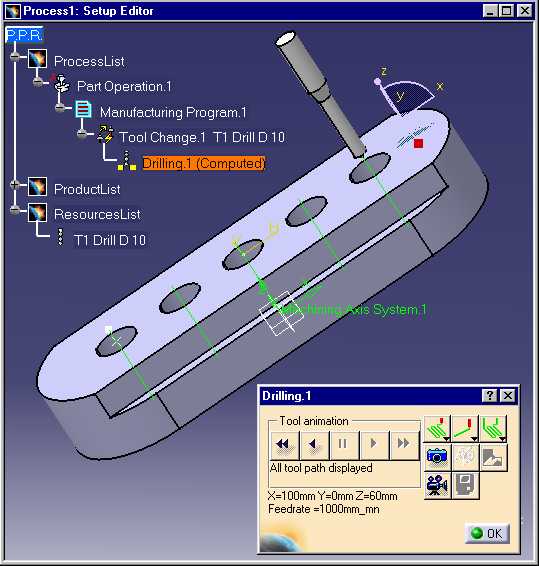

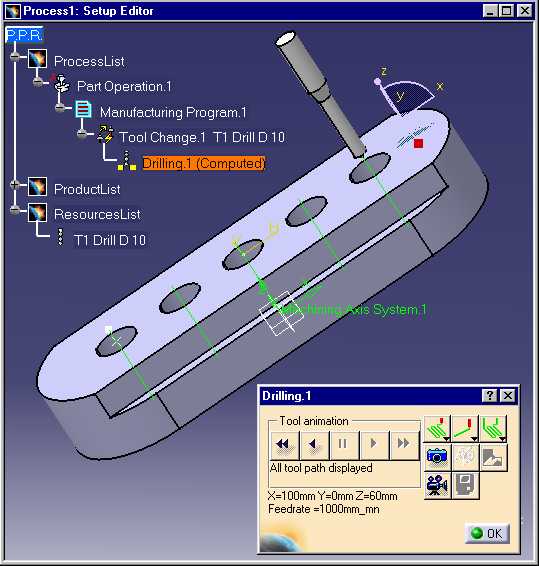

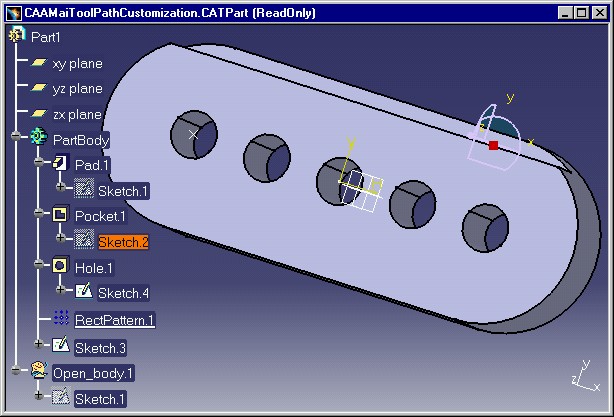

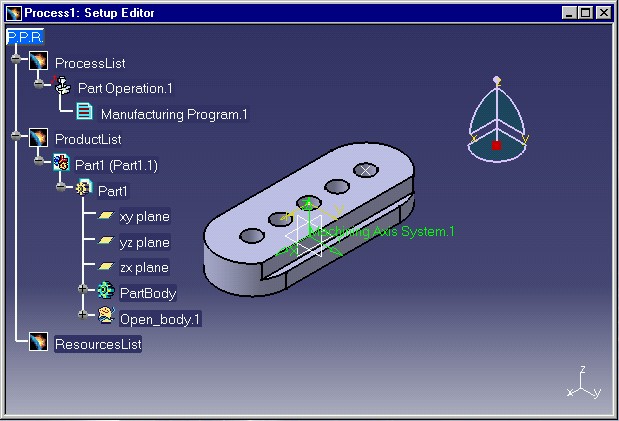

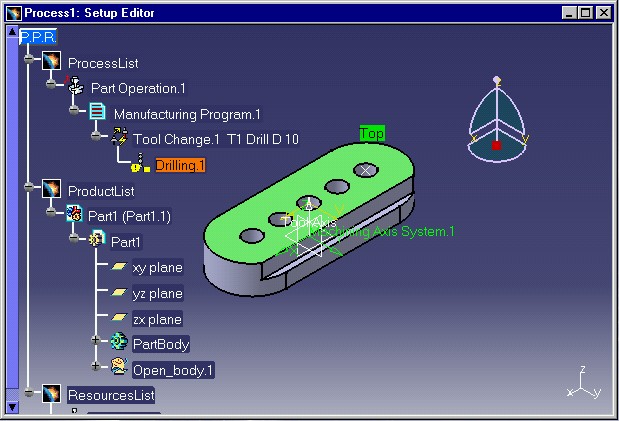

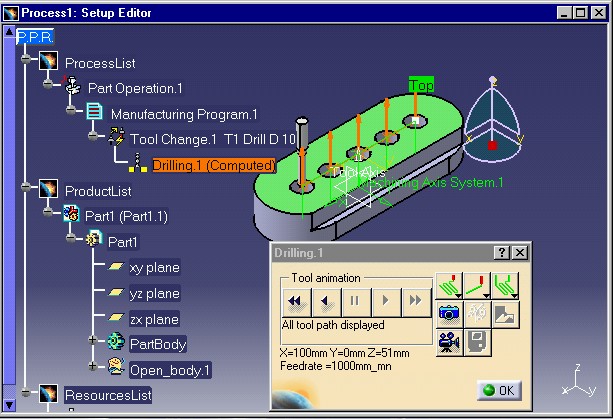

CAAMaiToolPathCustomization runs with the Process document shown on Fig.1 that contains the Drilling operation to use, the part to be machined, and the tool to use. The Drilling operation is accessible from the ProcessList, the part is in the ProductList, and the tool is stored in the ResourcesList. The five holes of the part are machined. The use case computes the tool path to enable the end user to replay the drilling operation.

|

[Top]

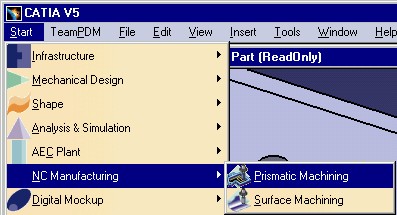

To launch CAAMaiToolPathCustomization, you will need to:

| Windows | InstallRootDirectory\CAADoc\CAAManufacturingItf.edu\CNext\code\dictionary\ |

| Unix | InstallRootDirectory/CAADoc/CAAManufacturingItf.edu/CNext/code/dictionary/ |

where InstallRootDirectory is the directory where the CAA

CD-ROM is installed, and decomment the following line by removing the '#'

character:

Drilling CATIMfgComputeToolPathCustom libCAAMaiToolPathCustomization

| Windows | InstallRootDirectory\CAADoc\CAAManufacturingItf.edu\CNext\resources\graphic\ |

| Unix | InstallRootDirectory/CAADoc/CAAManufacturingItf.edu/CNext/resources/graphic/ |

This displays the PPR document:

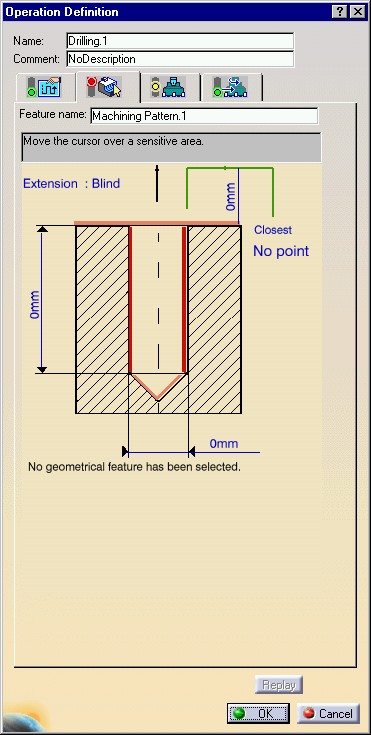

Note: at this step, the Drilling operation is not completed. The icon in the second tab page shows a red traffic light. The Replay push button is grayed. You have to select the geometry to machine.

[Top]

The CAAMaiToolPathCustomization use case is made of a class named CAAEMaiToolPathDrillingCustomization located in the CAAMaiToolPathCustomization.m module of the CAAManufacturingItf.edu framework:

| Windows | InstallRootDirectory\CAADoc\CAAManufacturingItf.edu\CAAMaiToolPathCustomization.m |

| Unix | InstallRootDirectory/CAADoc/CAAManufacturingItf.edu/CAAMaiToolPathCustomization.m |

where InstallRootDirectory is the directory where the CAA CD-ROM

is installed.

[Top]

There are four logical steps in CAAMaiToolPathCustomization:

We now comment each of those sections by looking at the code.

[Top]

The extension class that will implement CATIMfgComputeToolPathCustom is named CAAEMaiToolPathDrillingCustomization. Creating this class is done is three sub steps:

// Infrastructure interfaces

#include "CATBaseUnknown.h"

#include "CATIContainer.h"

// Manufacturing Interfaces

#include "CATIMfgToolPath.h"

class CAAEMaiToolPathDrillingCustomization : public CATBaseUnknown

{

// Used in conjonction with CATImplementClass in the .cpp file

CATDeclareClass;

public:

CAAEMaiToolPathDrillingCustomization();

virtual ~CAAEMaiToolPathDrillingCustomization();

// ComputeToolPath

//================

// Compute the tool path of the current Drilling operation

//

// ispContainer : Interface on the tool path container

// ospToolPath : Computed tool path

virtual HRESULT ComputeToolPath(const CATIContainer_var &ispContainer,

CATIMfgToolPath_var &ospToolPath);

private:

// Copy constructor, not implemented

// Set as private to prevent from compiler automatic creation as public.

CAAEMaiToolPathDrillingCustomization

(const CAAEMaiToolPathDrillingCustomization &iObjectToCopy);

// Assignment operator, not implemented

// Set as private to prevent from compiler automatic creation as public.

CAAEMaiToolPathDrillingCustomization & operator =

(const CAAEMaiToolPathDrillingCustomization &iObjectToCopy);

};

|

The CAAEMaiToolPathDrillingCustomization class C++-derives from CATBaseUnknown.

The CATDeclareClass macro declares that the class CAAEMaiToolPathDrillingCustomization

belongs to a component. The class has a constructor, a destructor, and the ComputeToolPath

method of CATIMfgComputeToolPathCustom, and a copy constructor.

Note that the copy constructor is set as private. This is very important for

extensions. Since extensions must never be directly instantiated by client

applications, this prevents the compiler from creating the copy constructor

as public without you know. This copy constructor is not implemented in the

source file.

...

#include "TIE_CATIMfgComputeToolPathCustom.h"

TIE_CATIMfgComputeToolPathCustom(CAAEMaiToolPathDrillingCustomization);

CATImplementClass(CAAEMaiToolPathDrillingCustomization,

DataExtension,

CATBaseUnknown,

Drilling);

...

HRESULT CAAEMaiToolPathDrillingCustomization::ComputeToolPath(const CATIContainer_var &spContainer,

CATIMfgToolPath_var &spToolPath)

{

HRESULT RC = E_FAIL;

...

|

The CAAEMaiToolPathDrillingCustomization class states that it

implements the CATIMfgComputeToolPathCustom interface thanks to the TIE_CATIMfgComputeToolPathCustom

macro. The CATImplementClass macro declares that the CAAEMaiToolPathDrillingCustomization

class is data extension class, thanks to the DataExtension

keyword, and that it extends the feature whose type is Drilling. The

third parameter must always be set to CATBaseUnknown, makes no sense,

and is unused for extensions.

Extending the Drilling feature using the CAAEMaiToolPathDrillingCustomization

class that implements CATIMfgComputeToolPathCustom means fitting this

feature with your customized behavior for drilling which will replace the

default one. The ComputeToolPath method implementation is shown

in the next steps. It has a smart pointer to the Process document

manufacturing container as input parameter, and a smart pointer to the

created tool path as output parameter.

Update the interface dictionary, that is a file named, for example in this case, CAAManufacturingItf.edu.dico, whose directory's pathname is concatenated at run time in the CATDictionaryPath environment variable, and containing the following declaration to state that the Drilling feature implements the CATIMfgComputeToolPathCustom interface, and whose code is located in the libCAAMaiToolPathCustomization shared library or DLL. Pay attention to remove the comment (#) in the supplied dictionary.

Drilling CATIMfgComputeToolPathCustom libCAAMaiToolPathCustomization

The CAAManufacturingItf.edu.dico file is located in:

| Windows | InstallRootDirectory\CAADoc\CAAManufacturingItf.edu\CNext\code\dictionary\ |

| Unix | InstallRootDirectory/CAADoc/CAAManufacturingItf.edu/Cnext/code/dictionary/ |

[Top]

The Manufacturing Activity parameters are:

The Manufacturing Activity parameters are retrieved as follows:

...

CATIMfgAxialOperation *piAxialOperationOnDrilling = NULL;

RC = QueryInterface(IID_CATIMfgAxialOperation,(void**) &piAxialOperationOnDrilling);

if (FAILED(RC))

return RC;

CATUnicodeString depthMode;

CATMathVector machiningToolAxis(0,0,0);

double clearTipValue = .0;

double depthValue = .0;

// -1.1-b Read Tip Approach Clearance 2nd Solution

RC = piAxialOperationOnDrilling->GetClearTip(clearTipValue);

if (SUCCEEDED(RC))

{

// -1.2- Read Tip Depth Mode : by Tip, by Shoulder, by Diameter

RC = piAxialOperationOnDrilling->GetDepthComputationMode(depthMode);

if (SUCCEEDED(RC))

{ // -1.3- Read the Machining Tool Axis

RC = piAxialOperationOnDrilling->GetOperationAxis(machiningToolAxis);

if (SUCCEEDED(RC))

{

// -1.4- Read the hole Depth

RC = piAxialOperationOnDrilling->GetFeatureDepth(depthValue);

}

}

}

piAxialOperationOnDrilling->Release();

piAxialOperationOnDrilling = NULL;

if (FAILED(RC))

return RC;

}

...

|

To get all the activity parameters, use the methods of the CATIMfgAxialOperation interface that the Drilling feature already implements.

The pattern data is read as follows:

...

// -1.5- Read Pattern Information

CATMathSetOfPoints pointsInPattern; // Points in the pattern

CATListOfDouble entryDistances; // Entry distances associated with the points

CATListOfDouble exitDistances; // Exit distances associated with the points

int nbOfPts = 0; // Number of points in the pattern

CATIMfgAxialToolPathGeneratorBase * piAxialTPGenBaseOnDrilling = NULL;

RC = QueryInterface(IID_CATIMfgAxialToolPathGeneratorBase,

(void**) &piAxialTPGenBaseOnDrilling);

if (SUCCEEDED(RC))

{

piAxialTPGenBaseOnDrilling->GetOperationPattern(pointsInPattern,

entryDistances, exitDistances, nbOfPts);

piAxialTPGenBaseOnDrilling->Release();

piAxialTPGenBaseOnDrilling = NULL;

}

else

return RC;

...

|

The GetOperationPattern method of the CATIMfgAxialToolPathGeneratorBase

interface implemented by the Drilling feature enables you to retrieve the

pattern as a set of points. This interface provides additional methods dedicated

to axial tool path computation.

[Top]

The tool parameters are read as follows:

...

//********************************************************************************************

// -2- Reading Tool Parameters

//********************************************************************************************

CATIMfgActivity_var spActivity(this);

if (NULL_var == spActivity)

return E_FAIL;

CATBaseUnknown_var spUnknownOnTool;

spUnknownOnTool = spActivity->GetTool();

if (NULL_var == spUnknownOnTool)

return E_FAIL;

CATIMfgTool * piToolOnTool = NULL;

RC = spUnknownOnTool->QueryInterface(IID_CATIMfgTool, (void**) & piToolOnTool);

if (FAILED(RC))

return E_FAIL;

// -3.1- Tool Diameter

double toolDiamValue = .0;

RC = piToolOnTool->GetValue(MfgNominalDiameter, toolDiamValue);

// -3.2- Way Of Rotation

CATUnicodeString wayOfRotation;

if (SUCCEEDED(RC))

RC = piToolOnTool->GetValue(MfgWayOfRotation, wayOfRotation);

piToolOnTool->Release();

piToolOnTool = NULL;

if (FAILED(RC))

return RC;

...

|

The activity is retrieved as a smart pointer to CATIMfgActivity, and

will be used to retrieve the tool and to initialize the tool path. The tool is

retrieved from the activity thanks to the GetTool method of CATIMfgActivity,

as a smart pointer to CATBaseUnknown. To get the tool parameter, a

pointer to CATIMfgTool must first be retrieved from the tool. The GetValue

method of CATIMfgTool enables you to retrieve the tool diameter thanks to

the keyword MfgNominalDiameter, and its way of rotation thanks to

the keyword MfgWayOfRotation.

Note that the keywords are defined in the CATMfgToolConstant.h file.

[Top]

...

CATIMfgToolPathFactory *piToolPathFactoryOnContainer = NULL;

RC= spContainer->QueryInterface(IID_CATIMfgToolPathFactory,

(void**) &piToolPathFactoryOnContainer);

if (FAILED (RC)) return E_FAIL;

//==============================

// Creation of tool path element

//==============================

CATIMfgCompoundTraject_var spCompoundTraject =

piToolPathFactoryOnContainer->CreateMfgCompoundTraject();

if (NULL_var == spCompoundTraject) return E_FAIL;

CATIMfgToolPathComponents_var spToolPathComponentsOnCompound(spCompoundTraject);

if (NULL_var == spToolPathComponentsOnCompound) return E_FAIL;

//=============================================================================

// Initialization of tool path from activity (copy of feedrates, spindle, ....)

//=============================================================================

spCompoundTraject->Init(spActivity);

//=========================================

// Initialization of tool axis on tool path

//=========================================

CATIMfgToolPathConstantToolAxis_var spToolAxis =

piToolPathFactoryOnContainer->CreateMfgToolPathConstantToolAxis(machiningToolAxis);

if (NULL_var == spToolAxis) return E_FAIL;

spCompoundTraject->SetToolAxis(spToolAxis);

//==================================================================================

// Creation of the objet dedicated to the description of motions

// This objet is linked to the tool path

//

// In the sample,only linear motions are described

// Note that it is also possible to describe circular motions and PP Instructions

// PP Instructions are described through NC_Commands and NC_Instructions of PP Table

//==================================================================================

CATIMfgTPMultipleMotion_var spMultipleMotion =

piToolPathFactoryOnContainer->CreateMfgTPMultipleMotion();

if (NULL_var == spMultipleMotion) return E_FAIL;

spToolPathComponentsOnCompound->AddElement(spMultipleMotion);

//==============================

// Description of linear motions

//==============================

CATMathPoint previousClearPoint;

for (int I = 1; I<=nbOfPts; I++)

{

CATListOfDouble X,Y,Z;

CATMathPoint point = pointsInPattern.GetPoint(I-1);

CATMathPoint clearPoint = point + machiningToolAxis * clearTipValue;

CATMathPoint depthPoint = point - machiningToolAxis * depthValue;

//=======================================================

// Linking traject in rapid feedrate between clear points

//=======================================================

if (I>1)

{

CATListOfDouble X2,Y2,Z2;

X2.Append (previousClearPoint.GetX());

Y2.Append (previousClearPoint.GetY());

Z2.Append (previousClearPoint.GetZ());

X2.Append (clearPoint.GetX());

Y2.Append (clearPoint.GetY());

Z2.Append (clearPoint.GetZ());

spMultipleMotion->AddPolyline (TPLinkingTraject,TPRapidFeedrate,X2,Y2,Z2);

}

//======================================

// Machining Traject to machine the hole

//======================================

X.Append (clearPoint.GetX());

Y.Append (clearPoint.GetY());

Z.Append (clearPoint.GetZ());

X.Append (depthPoint.GetX());

Y.Append (depthPoint.GetY());

Z.Append (depthPoint.GetZ());

X.Append (clearPoint.GetX());

Y.Append (clearPoint.GetY());

Z.Append (clearPoint.GetZ());

spMultipleMotion->AddPolyline (TPMachiningTraject,TPMachiningFeedrate,X,Y,Z);

previousClearPoint = clearPoint;

}

//========================

// Save tool path in model

//========================

CATIMfgTPSaveData_var spSaveData (spToolPathComponentsOnCompound);

if (NULL_var == spSaveData) return E_FAIL;

spSaveData->SaveData();

//======= // Return //======= ospToolPath = spToolPathComponentsOnCompound; if (NULL_var == ospToolPath) return E_FAIL; piToolPathFactoryOnContainer->Release(); piToolPathFactoryOnContainer = NULL; return RC; } |

The tool path is created and returned as a CATIMfgCompoundTraject

smart pointer using the CreateMfgCompoundTraject method of the CATIMfgToolPathFactory

interface implemented by the Process document manufacturing container passed as

input parameter. Then, a smart pointer to CATIMfgToolPathComponents is

retrieved from the tool path and the tool path is initialized from the activity

using the Init method of CATIMfgCompoundTraject. The tool

axis is created thanks to the CreateMfgToolPathConstantToolAxis

method of CATIMfgToolPathFactory to which the machining tool axis

retrieved in the data reading step is passed. This tool

axis is set to the tool path using the SetToolAxis method of CATIMfgCompoundTraject.

The tool path data can now be created from the pattern. First, a set of points is created and filled in, for each point in the pattern, with:

The CreateMfgTPMultipleMotion method of CATIMfgToolPathFactory

creates the object which contains the motions (linear or circular motion) and PP

Instructions (NC_Command). This object is added to the tool path thanks to the AddElement

method of CATIMfgToolPathComponents.

In this sample, two linear motions are stored for each point of the pattern :

TPLinkingTraject)

in rapid feedrate (TPRapidFeedrate) between the previous hole

to the current one.TPMachiningTraject) in machining

feedrate (TPMachiningFeedrate) to machine the current point.With interface CATIMfgTPSaveData on tool path, the tool path is saved

in the model with the method SaveData.

Then, the tool path is passed to the output parameter as a pointer to CATIMfgToolPath.

Note that the keywords such as TPMachiningFeedrate, TPMachiningTraject, used for tool path computation are located in the CATMfgToolPathDefs.h file.

[Top]

This article provides an example on how to use the manufacturing interface classes, and has illustrated them on a axial tool path customization. It shows how to implement the CATIMfgComputeToolPath interface to compute the tool path of a drilling operation in a process document that includes this operation as an activity, and that also include the part to be machined, and the tool resources.

The Drilling feature behavior is modified by implementing CATIMfgComputeToolPath

in a data extension class. The only method to implement is ComputeToolPath,

to successively retrieve the manufacturing parameters from the activity thanks

to methods of either the CATIMfgActivityParameters interface, or to the CATIMfgAxialOperation

interface, both implemented by the Drilling feature. The pattern is

retrieved thanks to the CATIMfgAxialToolPathGeneratorBase interface also

implemented by the Drilling feature, and the tool parameters are

retrieved using the CATIMfgTool interface.

The tool path is created and handled as a CATIMfgCompoundTraject

pointer using the CreateMfgCompoundTraject method of the CATIMfgToolPathFactory

interface implemented by the Process document manufacturing container. The tool

axis, and the object that makes up the tool path created from the pattern as a CATIMfgTPMultipleMotion,

are set or added to the tool path handled as a CATIMfgToolPathComponents.

Then, the tool path is passed to the output parameter as a pointer to CATIMfgToolPath.

[Top]

| [1] | Building and Launching a CAA V5 Use Case |

| [2] | Process Modeler Home Page |

| [Top] | |

| Version: 1 [Sep 2000] | Document created |

| [Top] | |

Copyright © 2000, Dassault Systèmes. All rights reserved.