AbstractThis article discusses the CAAStmSurfacicFlange use case. This use case explains how to create or modify a Surfacic Flange feature. A Surfacic Flange is a feature to stiffen another aerospace sheet metal feature.[1]

|

This use case learns how to use the aerospace sheet metal factory and the Surfacic Flange public interface to create , display or modify a Surfacic Flange. Its main intent is to introduce important concepts about the way to create or modify aerospace sheet metal features.

CAAStmSurfacicFlange is a use case of the CAAAerospaceSheetMetal.edu framework that illustrates the creation or modification of a Surfacic Flange feature.

This use case will show you the different steps to create or modify a Surfacic Flange.

More precisely this sample :

- Read and analyse an input data (.txt) file.

- Create a session.

- Open a CATPart document including the necessary geometric input features.

- Create the Surfacic Flange feature no Surfacic Flange is asked to modify.

- Set the values of the parameters of the Surfacic Flange.

- Update the Part.

- Save the result in a new CATPart document.

- Close the session.

With this sample, you will have in batch mode the same capabilities than an interactive session.

The input data file contains the same fields than the UI Surfacic Flange command panel :

Some samples of input data are provided in Data.d directory.

The structure of this file is simple :

KEYWORD: when a keyword is encountered a boolean is set to TRUE : the corresponding data is to set.

More details about available KEYWORDS are provided in front of the sample source file.

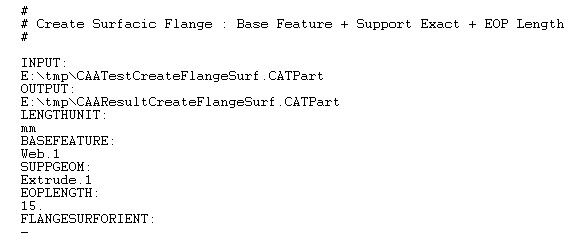

i.e. : The input data file above will create a Surfacic Flange with features read in CAATestCreateFlangeSurf.CATPart :

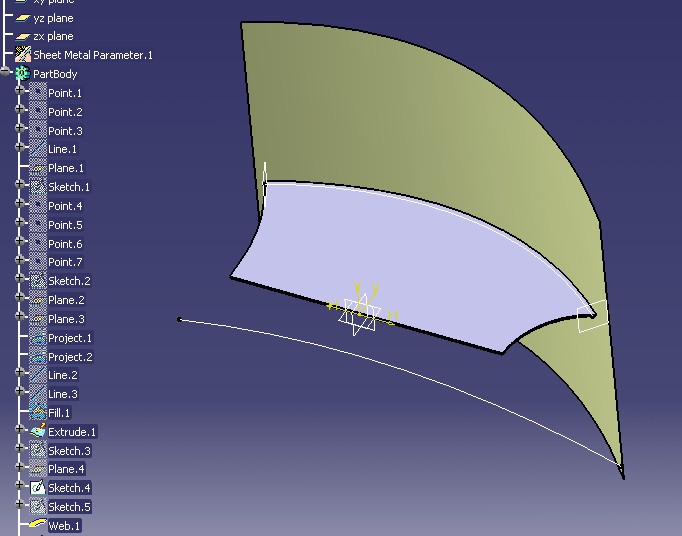

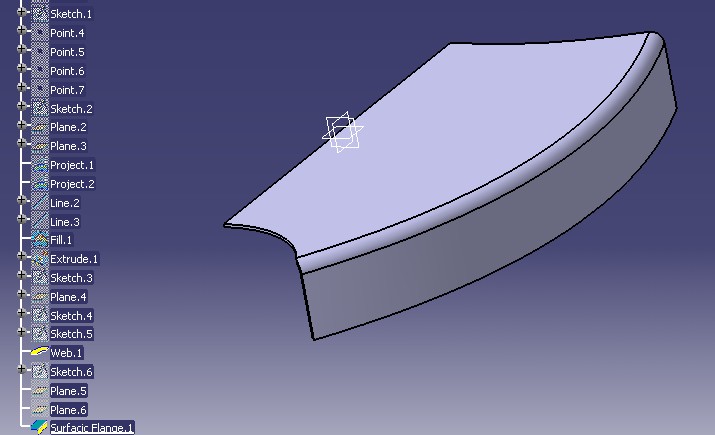

Remark that the Sheet Metal Parameters feature and the Base Feature (i.e. : Web.1 ) must exist in the input Part ( see the spec tree above ).

The sample will create a SurfacicFlange with Web.1 as Base Feature and Extrude.1 as Support :

[Top]

To launch CAAStmSurfacicFlange, you will need to set up the build time environment, then compile CAAStmSurfacicFlange along with its prerequisites, and set up the run time environment, and then execute the use case [2].

Launch the use case as follows:

Edit the File : CAATestCreateFlangeSurf.txt Customize the fields INPUT and OUTPUT Specify the Paths where the .CATParts files will be retrieved and saved |

e:\CAAStmSurfacicFlange inputDirectory\CAATestCreateFlangeSurf.txt |

$ CAAStmSurfacicFlange inputDirectory/CAATestCreateFlangeSurf.txt |

where:

inputDirectory |

The directory into which CAATestCreateFlangeSurf.txt is found

|

[Top]

The CAAStmSurfacicFlange use case is made of main program located in the CAAStmSurfacicFlange.m module of the CAAAerospaceSheetMetal.edu framework:

| Windows | InstallRootDirectory\CAAAerospaceSheetMetal.edu\CAAStmSurfacicFlange.m\ |

| Unix | InstallRootDirectory/CAAAerospaceSheetMetal.edu/CAAStmSurfacicFlange.m/ |

The input CAATestCreateSurfacicFlange.txt and CAATestCreateSurfacicFlange.CATPart are proposed in Data.d directory of CAAAerospaceSheetMetal.edu

| Windows | InstallRootDirectory\CAAAerospaceSheetMetal.edu\Data.d\SurfacicFlange

|

| Unix | InstallRootDirectory/CAAAerospaceSheetMetal.edu/Data.d/SurfacicFlange |

where InstallRootDirectory is the directory where the CAA

CD-ROM is installed.

[Top]

There are 7 main steps in CAAStmSurfacicFlange :

We will now comment each of those sections by looking at the code of the main method of the file CAAStmSurfacicFlange.cpp.

[Top]

CAAStmSurfacicFlange sample will first read and analyse an input data file.

Note : some services are provided in the class CAAStmServices.

...

CAAStmServices CAASmaTools;

rc = CAASmaTools.AnalyseSurfacicFlangeInputData (InputDataFilePath, CAASurfacicFlangeInput);

...

|

The method AnalyseSurfacicFlangeInputData will read the input data file and store the data in the class CAAStmInputData : i.e : if the method GetSupportGeomToSet () returns TRUE it means that the Support is to set.

...

class ExportedByCAAStmServices CAAStmInputData

{

public:

CAAStmInputData();

virtual ~CAAStmInputData();

/**

* Role: Methods to get the Input Data.

*

*/

// General Data :

// --------------

CATUnicodeString GetInputPartPath ();

CATUnicodeString GetOutputPartPath ();

CATUnicodeString GetLengthUnit ();

CATBoolean GetDisplay ();

...

|

[Top]

Create a session and open the CATPart Document : this step has no specificity. It is a call to standard functionalities :

...

// create a session

char * pSessionName = "CAAStmSurfacicFlange";

CATSession * pSession = NULL;

rc = Create_Session (pSessionName, pSession);

...

// Load the input Document

rc = CATDocumentServices::OpenDocument((CAAFlangeInput.InputPartPath).ConvertToChar(), pDocument);

...

// Retrieve the Part Feature and the Aerospace Sheet Metal Factory :

CATIPrtContainer * piPrtCont = (CATIPrtContainer *) piInit -> GetRootContainer("CATIPrtContainer");

if(NULL != piPrtCont)

{

spPrtPartSpec = piPrtCont -> GetPart();

if(NULL_var != spPrtPartSpec)

{

...

rc = piPrtCont -> QueryInterface(IID_CATIAerospaceSheetMetalFactory, (void **)& piAslFactory);

...

|

[Top]

Create a SurfacicFlange feature using CreateSurfacicFlange method of CATIAerospaceSheetMetalFactory : this method will create all internal features and links between the attributes of the SurfacicFlange. If a modification is asked the Surfacic Flange will be retrieved :

...

if(CAAFlangeInput.GetModifFlange())

{

// Try to retrieve the SurfacicFlange Feature :

rc = CAASmaTools.FindFeatureInSpecTree (spPrtPartSpec, CAAFlangeInput.ModifFlangeName, &piFlangeSurfSpec);

...

else

{

// creation of a new SurfacicFlange

rc = piAslFactory -> CreateSurfacicFlange ((CATISpecObject *) spPrtPartSpec, &piFlangeSurfSpec);

...

|

[Top]

Set the SurfacicFlange parameters according to the the values stored in CAAFlangeInput

i.e : Support Geometry : set a CATISpecObject pointer

...

if(SUCCEEDED(rc) && (CAAFlangeInput.GetSupportGeomToSet()))

{

// Search the Support input specification :

CATISpecObject * pSupportSpec = NULL;

rc = CAASmaTools.FindFeatureInSpecTree (spPrtPartSpec, CAAFlangeInput.SupportGeomName, &pSupportSpec);

if(SUCCEEDED(rc) && (NULL != pSupportSpec))

{

// Set the Support Geometry :

rc = piStmFlangeSurf -> SetSupport (pSupportSpec);

...

|

i.e : EOP : Length From OML : Valuate a CATICkeParm pointer

...

if(SUCCEEDED(rc) && (CAAFlangeInput.GetEOPLengthToSet()))

{

if((CAAFlangeInput.EOPTypeName) == "Length From OML")

{

CATICkeParm * piEOPLengthParam = NULL;

rc = piStmFlangeSurf -> GetEOPLength (&piEOPLengthParam);

if(SUCCEEDED(rc) && (NULL != piEOPLengthParam))

{

// Valuate the Literal ::

double MKSVal = CAASmaTools.ConvertLengthToMKS (CAAFlangeInput.LengthUnit,

CAAFlangeInput.EOPLengthValue); // MKS Units

piEOPLengthParam -> Valuate(MKSVal);

...

|

i.e : Base Feature orientation : set a CATOrientation

...

if(SUCCEEDED(rc) && (CAAFlangeInput.GetBaseFeatureOrientToSet()))

{

rc = piStmFlangeSurf -> SetBaseFeatureOrient (CAAFlangeInput.BaseFeatureOrient);

...

|

[Top]

We suggest to update the Part Feature instead of the SurfacicFlange to force all internal links of the SurfacicFlange to re-build :

This step is not necessary if "DISPLAY:" has been chosen.

Before updating the Surfacic Flange it is necessary to check the internal links :

...

// Check Surfacic Flange Internal Structure before updating :

if(SUCCEEDED(rc))

{

rc = piStmFlangeSurf -> CheckInternalStructure ((CATISpecObject *) spPrtPartSpec);

...

|

Update the Part :

...

// Update the Part : to ensure all internal Surfacic Flange links to re-build

rc = CAASmaTools.Update ((CATISpecObject *) spPrtPartSpec);

...

|

[Top]

Save the result Part in a new CATPart file.

This step is not necessary if "DISPLAY:" has been chosen.

...

// Save the Document

rc = CATDocumentServices::SaveAs (*pDocument, (CAAFlangeInput.OutputPartPath).ConvertToChar());

...

|

[Top]

Release the interface pointers and close the session.

...

// Releases on Interfaces :

if(NULL != piAslFactory)

{

piAslFactory -> Release();

piAslFactory = NULL;

}

if(NULL != piPrtPartSpec)

{

piPrtPartSpec -> Release();

piPrtPartSpec = NULL;

}

if(NULL != piStmFlangeSurf)

{

piStmFlangeSurf -> Release();

piStmFlangeSurf = NULL;

}

if(NULL != piFlangeSurfSpec)

{

piFlangeSurfSpec -> Release();

piFlangeSurfSpec = NULL;

}

// Close the document

rc = CATDocumentServices::Remove (*pDocument);

...

// End session

rc = Delete_Session (pSessionName);

...

|

[Top]

This use case has demonstrated the way to create, display or modify a Surfacic Flange feature.

[Top]

| Version: 1 [January 2005] | Document created |

| [Top] | |

| [1] | An Overview of the Aerospace Sheet Metal Design Features |

| [2] | Building and Launching a CAA V5 Use Case |

| [Top] | |

Copyright © 2004, Dassault Systèmes. All rights reserved.